How much do you know about the high-voltage cable branch box?

Release Date:2021-05-06 Author: Click:

1 Overview:

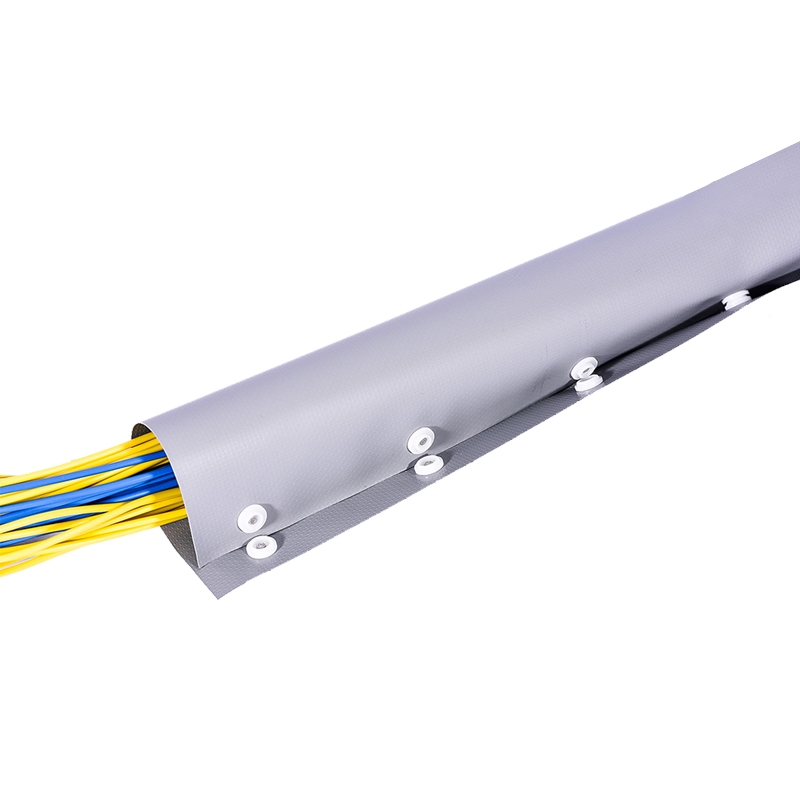

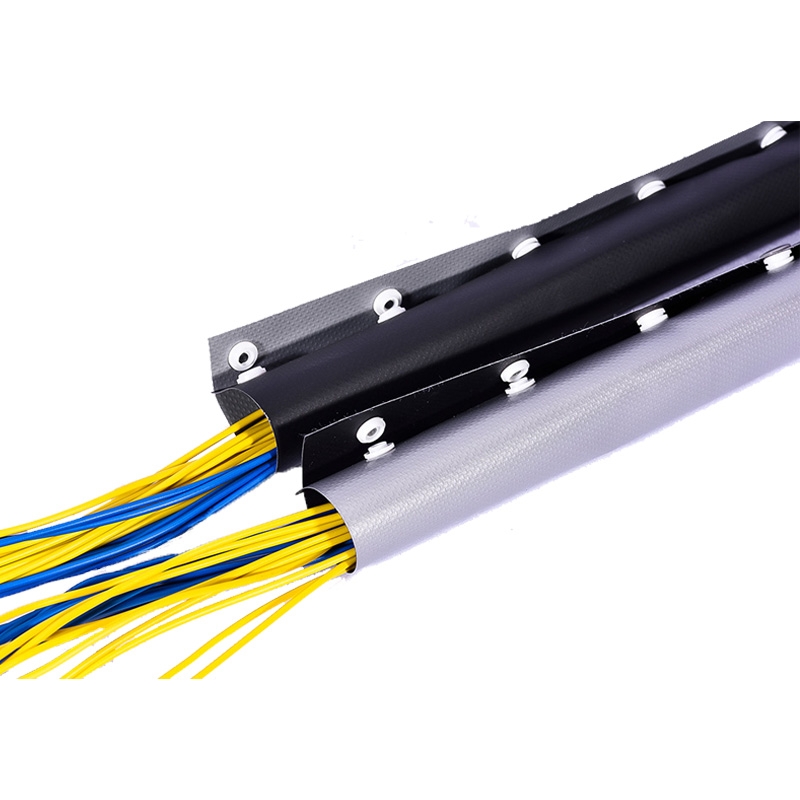

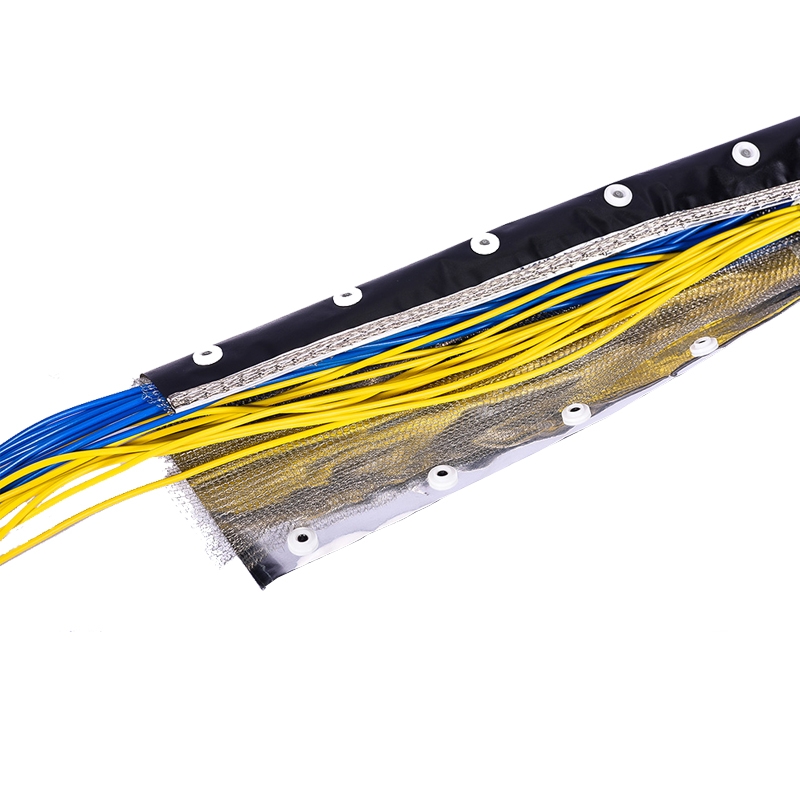

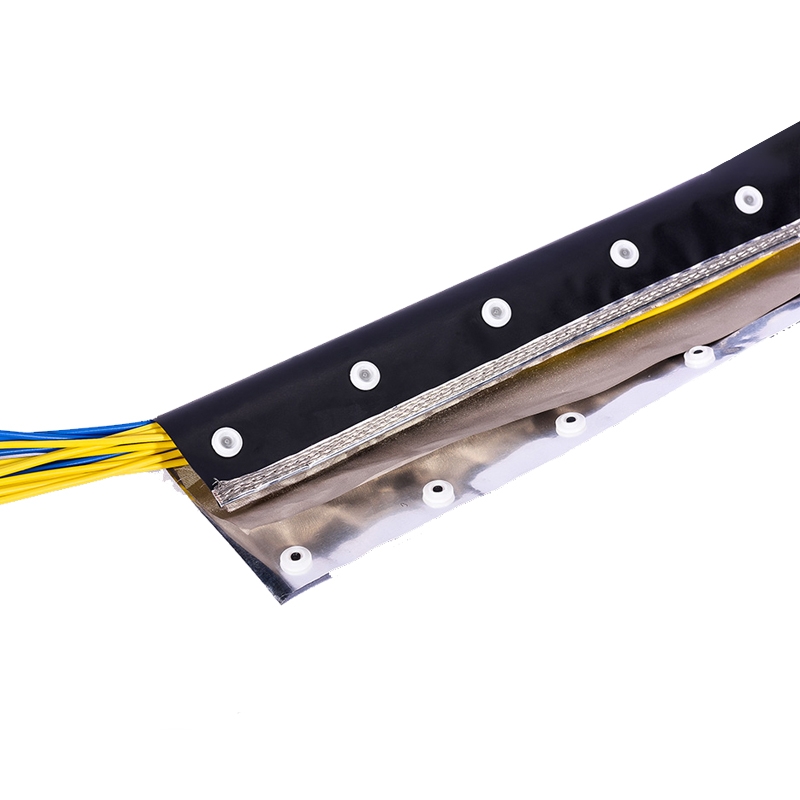

EY.DFW□-12 outdoor high-voltage cable junction box is an outdoor high-voltage electrical equipment with a rated voltage of 12kV and a rated current of 630A and below. It is widely used for the connection and branching of power cables.

2. Applicable places:

Buckle-type bushing products are widely used in the connection and branching of cables in the power system of 10kV and below. The connection method is simple, flexible, convenient, safe and reliable. The box body is made of stainless steel, which is strong and durable. The live part is a fully insulated and fully sealed structure. If a flood-proof touchable cable head is used, it can also be resistant to flooding, which greatly improves the reliability of power supply. This product is widely used in the distribution network of urban industrial districts, residential districts, commercial centers, mining areas, airports, railways, wind power stations, opening and closing stations, steel, petroleum, chemical, cement and other large enterprises and other occasions. It is especially suitable for urban road power grid reconstruction projects, which can greatly save electrical equipment and cable investment. Improve power supply reliability.

3. Normal use conditions:

3.1 Altitude 2000 m

3.2 Higher ambient temperature + 55 ℃

3.3 Lower ambient temperature -40 ℃

3.4 Sunlight intensity 0.1W/cm? (Wind speed: 0.5m/s)

3.5 Large daily temperature difference 25K

3.6 Indoor relative humidity: daily average ≤95%, monthly average ≤90%

3.7 Larger wind speed 35m/s (Note: Wind speed refers to the average wind speed of 10 minutes at a height of 10m from the ground)

3.8 Load with 10mm icing and 17.5m/s wind speed at the same time

3.9 Earthquake resistance ability The horizontal acceleration is 0.2g; the vertical acceleration is 0.1g at the same time. Safety factor ≥1.67.

3.10 System rated frequency: 50Hz

3.11 Installation location Outdoor

4. Structural performance characteristics

The cable junction box is an outdoor high-voltage switchgear, so it must have the functions of rainproof, rustproof, ventilation and heat dissipation, electric shock prevention, anti-theft, and convenient installation and maintenance. The outdoor cable distribution box produced by our company has louvers (welded with Φ1 steel wire mesh) air inlets on the lower sides of the box body; air outlets are provided on the top cover of the box body, hidden under the roof eaves, and the top cover is an air interlayer Double-layer structure; the base of the box is equipped with detachable partitions, cable inlet and outlet and ventilation holes to prevent small animals from entering. In this way, bottom-up convection air is formed, so that the box has good heat insulation, ventilation and rainproof effects. Spray eye-catching "High Voltage Danger" warning texts and warning symbols on obvious locations on the outer surface. The door lock adopts the double protection measures of bolt and padlock to prevent electric shock and theft. A live display buckle-type sleeve device with incoming and outgoing cables is installed in an obvious position in the box. In order to facilitate the maintenance and repair of the line, improve the flexibility of the operation mode, and reduce the power outage time of the line, the load switch can be connected with the relevant cable joint accessories to become a cable branch box with a switch. The switch can directly break the load current to improve the reliability of power supply. Fully insulated, fully sealed, and full working conditions. Under the condition that does not affect the operation of the main network, regional power outage maintenance can be realized. It can replace part of the ring network cabinet and reduce the project cost. Configure maintenance-free SF6 load switch. It has all the technical characteristics of ordinary cable junction box.

5. SF6 three-station load switch

There are 3 states: closed, open, and grounded.

Use SF6 as arc extinguishing and insulating medium.

The SF6 air pressure in the load switch is 0.04MPa (20℃)

The load switch has a long mechanical life, 30 years of lifetime sealing and maintenance-free

The three-position load switch can only be placed in any one of the three positions of closing, opening and grounding to prevent misoperation. The cable room can only be entered when the load switch is in the grounded state

6. Test standards and requirements

According to the newer version of IEC standards and national standards (GB) for testing. During the test, the following additional requirements and IEC supplementary instructions must be followed and implemented. The specified items and methods are tested, and the test results meet the requirements of the corresponding clauses of this technical specification.

6.1 Type test

6.1.1 Insulation test: a) Lightning impulse withstand voltage test b) Power frequency withstand voltage test

6.1.2 Temperature rise test The temperature rise test must be carried out in accordance with the GB/T 11022 standard.

6.1.3 Main circuit resistance measurement

6.1.4 Dynamic and thermal stability test of main circuit and grounding circuit

6.1.5 Protection level inspection

6.1.6 Internal arcing test

6.1.7 Earthquake test

6.2 Factory test

6.2.1 Carry out tests according to GB3804 and GB16926 stipulated items, and provide factory factory standards.

6.2.2 Each accessory is tested in the factory. The test items: a) Structural inspection b) Mechanical operation and mechanical characteristics c) Power frequency withstand voltage test of the main circuit d) Withstand voltage test of the control circuit and auxiliary circuit e) Main circuit resistance measurement

6.3 On-site test According to the relevant items and standards of the "Electric Power Equipment Handover and Preventive Test Regulations" of Jiangsu Electric Power Company.

7. Transportation, installation and operation and maintenance

7.1 Sign

7.1.1 Each product shipped from the factory has a nameplate, which should indicate: a) the name and trademark of the manufacturer; b) the product name and model; c) the rated voltage; d) the rated current; e) the rated frequency; f ) Rated short-time withstand current; g) Rated lightning impulse withstand voltage; h) Rated short-circuit closing current; i) Total weight (kg); j) Manufacturing year and month; k) Factory serial number.

7.2 Packaging and transportation 7.2.1 The packaging is in compliance with the factory standard specifications to ensure that the product will not be damaged, cracked, deformed, lost or damp during transportation; the insulating parts and insulators are specially protected to avoid cracks and scratches; exposed to the outside

The conductive contact surface is coated with antifreeze conductive paste at the same time. All transportation measures should be verified. During transportation, it must not be turned upside down, and must not be subjected to strong vibrations and collisions. 7.2.2 The products are packaged in moisture-proof and shock-proof packaging, and the packaging boxes are marked with obvious signs such as "Handle with care", "Do not turn upside down" and "Rain-proof and moisture-proof". There are the following text or symbols on the packing box: Product model, name and quantity; Company name and address; Name and address of the receiving unit; Outer dimensions of the box (length * width * height); weight (net weight, gross weight) kg . 7.2.3 Each product certificate (including factory inspection data) and installation instructions are delivered with the box. 7.2.4 The product should be inspected and tested in accordance with the requirements of the instruction manual before use.

7.3 Installation, all provided instructions include the following: 7.3.1 Special tools, working procedures and methods for unpacking and lifting; 7.3.2 The inspection and test items and requirements after the installation of the switch are given.

7.4 Operation and maintenance

7.4.1 The manufacturer shall provide instructions and precautions for the maintenance work content.

7.4.2 The operating mechanism should provide the following contents: a. Maintenance and inspection cycle and criteria for temporary inspection; b. Maintenance and inspection procedures and matters needing attention.

7.4.3 The following content should be given for the electrical connection: a. Under what circumstances should the electrical connection be protected from electrochemical corrosion; b. Which electrical connection parts should be inspected; c. The process standard for electrical connection maintenance.

7.4.4 The technical documents should be submitted to the user together with the product: 1) packing list; 2) product manual; 3) product installation and operation manual; 4) spare parts list; 5) equipment list.