How is the perfect electrical control cabinet designed?

Release Date:2021-05-05 Author: Click:

A good electrical control cabinet is inseparable from the skilled craftsmanship of the workers, and it is also inseparable from the scientific and useful planning of the planner. How can we plan a qualified electrical control cabinet? Let’s talk about the basic ideas and guidelines for the planning of electric control cabinets.

(I. Overview

Summarize and calculate the various parts and data required by the electrical control cabinet, and list the summary list of purchased finished parts, the list of standardized parts, the primary data consumption quota and the auxiliary data quota, etc. by category, so as to facilitate purchasers and production The management department prepares materials according to equipment production requirements and prepares for production, which is also convenient for cost accounting.

The basic idea of electrical control cabinet planning is a kind of logical thinking. As long as it conforms to the logical control rules, can ensure electrical safety and meet the requirements of the production process, it can be said to be a good plan. However, in order to meet the production and use requirements of electrical control equipment, it is necessary to make a reasonable electrical control button end belt process planning. These plans include the structural plan of the electrical control cabinet, the overall equipment diagram of the electrical control cabinet, the overall wiring diagram planning, and the electrical equipment diagrams and wiring diagrams of each part, as well as part of the component catalog, entry and exit line numbers and primary information list, etc. Skill information.

(2) Overall equipment planning of the electric control cabinet

The overall equipment planning task of the electrical control cabinet is based on the operating principle and control requirements of the electrical schematic diagram. A part is divided into several components, and then the incoming and outgoing wire numbers of each part are sorted out according to the wiring connection of the electrical schematic diagram, and the connection method between them is adjusted. The overall equipment plan is expressed by the method of the general equipment diagram and the general wiring diagram of the electrical system. The diagram should reflect the position of the main components of each part and the connection of each part, the wiring method and the line trough used in the schematic method. Pipeline and so on.

The overall equipment diagram and wiring diagram of the electrical control cabinet (which can be separated or combined according to requirements) are the basis for division planning and coordination of various parts into a complete system. The overall planning should make the entire electrical control system converge and compact, and place heating components and electrical components with large noise and vibration as far away as possible from other components or block them when space permits; For large-scale equipment, the convenience of operations in two places should also be considered; the main power switch and emergency stop control switch of the control cabinet should be placed in a convenient and obvious position.

Whether the overall equipment planning is reasonable or not is related to the production of the electrical control system and the quality of the equipment. It will also affect the realization of the performance of the electrical control system and the reliability of the operation, the convenience and quality of operation, debugging, protection and other operations.

2.1 The distinction of electrical control cabinet components, due to the different orientations of various electrical components and equipment, it is necessary to distinguish the components when forming a complete electrical control system. The criteria for distinguishing between buckle end strap components are:

● Combine components with similar functions together;

● Reduce the number of connections between components as much as possible, and put the control appliances with close connections in the same component together;

● Separate the strong and weak current controllers to reduce interference;

● In order to be neat and beautiful, the electrical appliances near the shape and weight can be combined together;

● In order to facilitate the inspection and debugging of the electrical control system, the components that need frequent conditioning, protection, and damage are combined together.

2.2 When distinguishing the components of the electrical control cabinet, it is necessary to solve the wiring method between the components, between the electrical boxes and between the electrical box and the controlled equipment; the wiring methods between the parts and components of the electrical control cabinet should generally follow the following guidelines :

● The incoming and outgoing wires of switch electrical appliances and control panels are generally connected by terminal heads or wiring noses, which can be connected with different specifications according to the current size and the number of incoming and outgoing wires;

● Between electrical cabinets, control cabinets, cabinets (sets) and between them and the controlled equipment, use terminal blocks or industrial connectors to connect;

● Various types of standardized connectors should be used for connection between weak current control components and printed circuit board components; +

● The connection between the components in the electrical cabinet, the control cabinet and the cabinet (station) can be directly connected by the component's own terminal; the transition connection should be connected with the terminal block, and the end should be handled with the corresponding standard terminal.

(3) Planning and production of electrical component placement plans

The electrical component placement diagram is a combination of certain electrical components according to certain criteria. The planning basis of the electrical component placement diagram is the schematic diagram of the components, the distinguishing status of the components, etc. The following guidelines should be followed when planning:

● For the placement of electrical components in the same assembly, attention should be paid to placing large and heavier electrical components under the electrical board, and heating components should be placed on the upper or rear of the electrical control cabinet, but the thermal relay should be placed under it. The outlet end of the thermal relay is directly connected to the motor for easy outlet, and its inlet end is directly connected with the contactor, which is convenient for wiring and makes the wiring shorter, and suitable for heat dissipation.

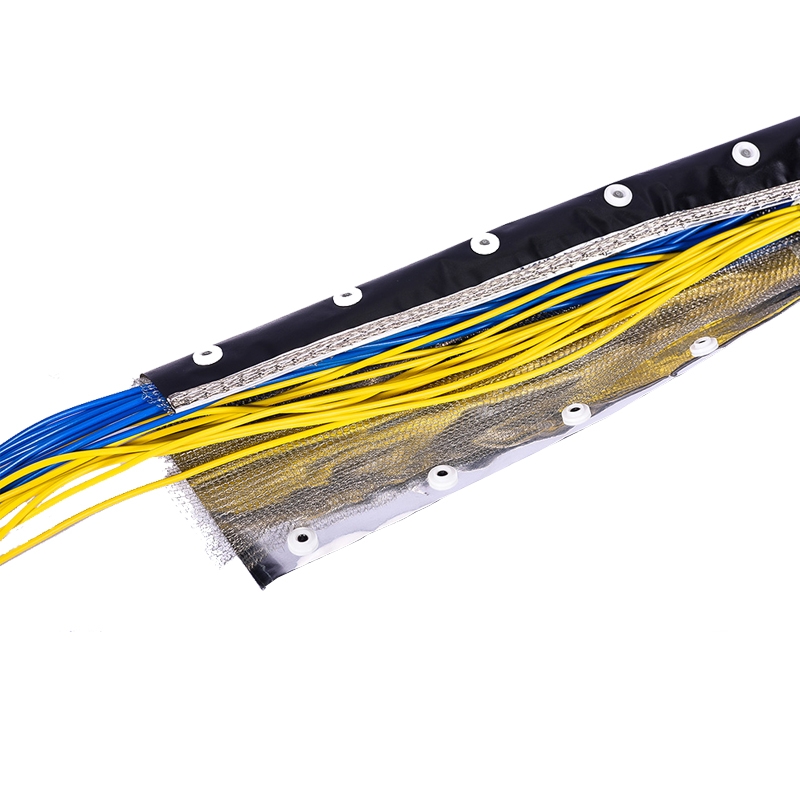

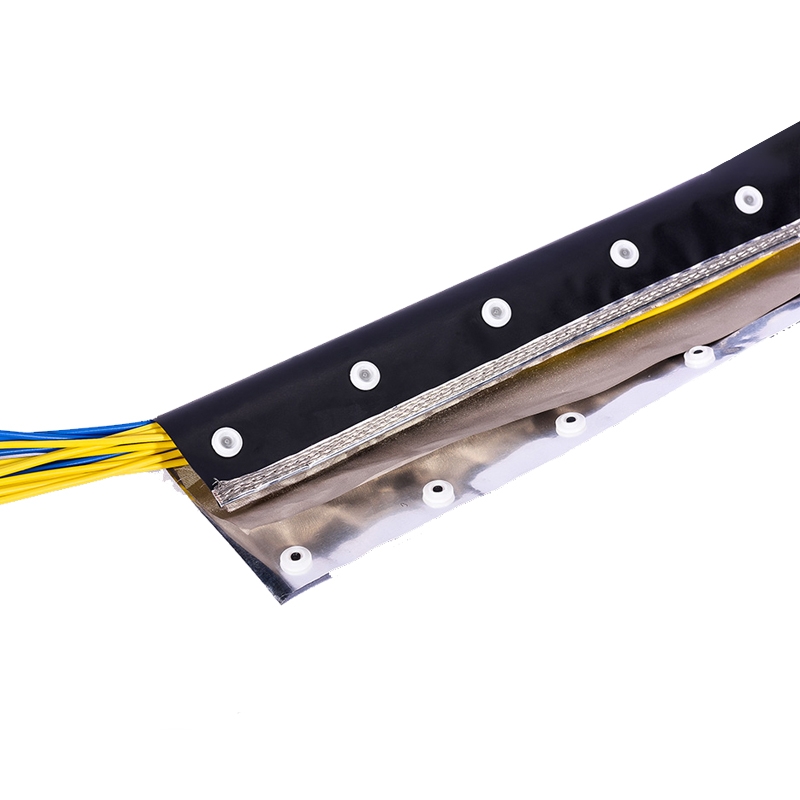

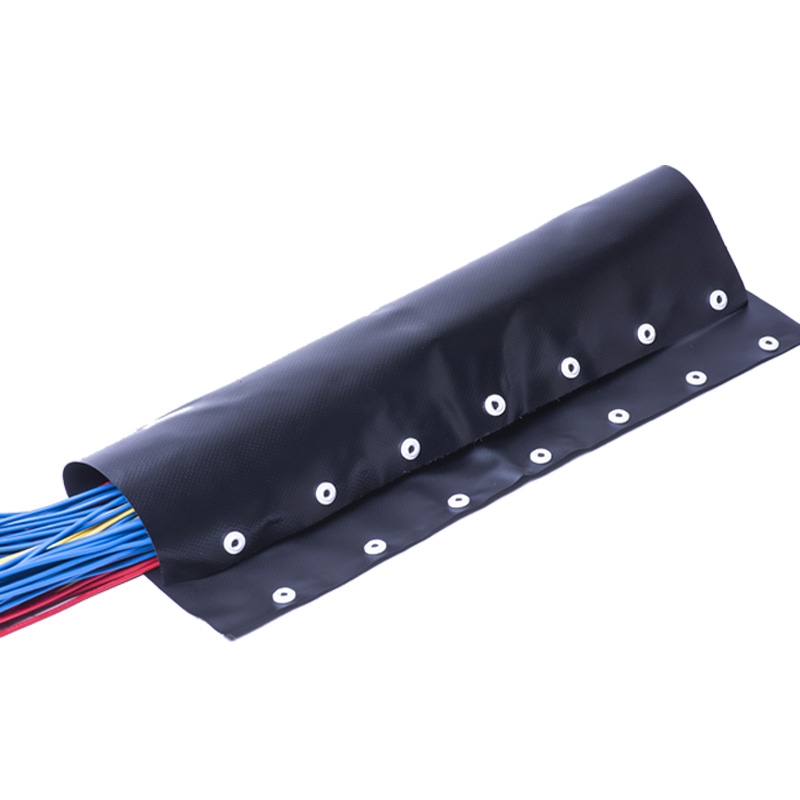

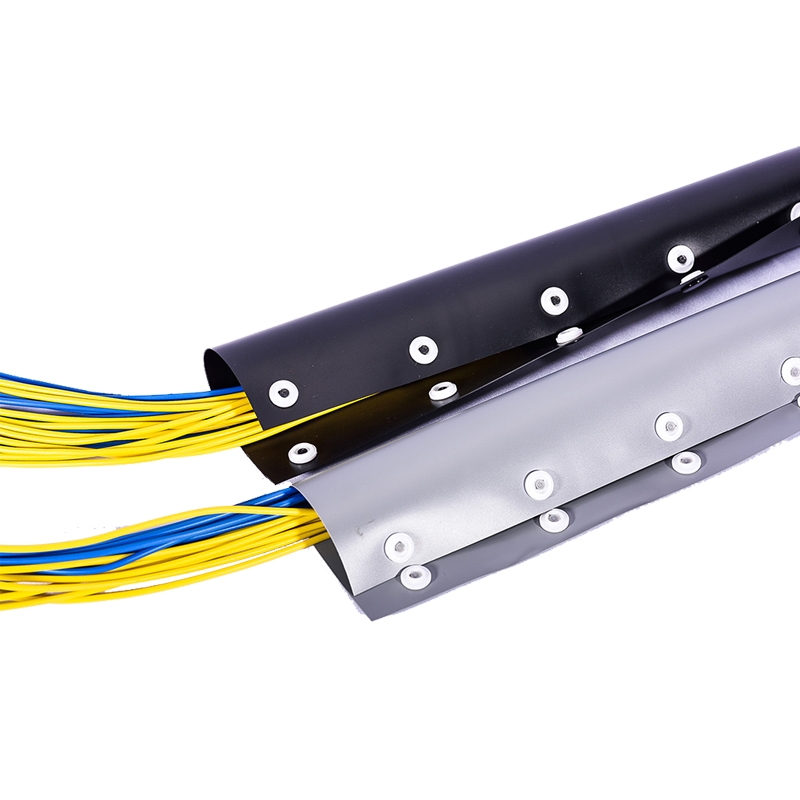

● Separate strong and weak currents and pay attention to shielding to avoid external disturbance.

● The orientation of electrical components and equipment that require frequent protection, maintenance, and adjustment should not be too high or too low. The orientation of the equipment for manual operation of switches and instruments that need to be monitored frequently should conform to the principles of ergonomics.

● The placement of electrical components should consider safety gaps, and be neat, beautiful, and symmetrical. Electrical appliances with similar dimensions and structures can be placed together to facilitate processing, equipment and wiring; Properly increase the distance between each row of electrical appliances to facilitate wiring and protection.

● After the location of each electrical component is determined, the electrical placement map can be made. The electrical arrangement diagram is generally made according to the appearance of the electrical components, that is, the distance scale of each component is marked with its axis as the standard. The equipment scale of each electrical component and its public service scale should be marked in accordance with the specifications in the product specification to ensure the processing quality of the equipment board and the smooth equipment of each electrical appliance. The electrical components in a large electrical cabinet should be installed between the two equipment beams. This can reduce the weight of the cabinet, save data, and facilitate equipment. Therefore, the longitudinal equipment size should be calculated during planning.

● In the electrical installation plan planning, according to the number of incoming and outgoing wires of this component, the selection of wire specifications and the outgoing direction, etc., select the incoming and outgoing method and the terminal block, connector or connector, and mark the wiring of the incoming and outgoing wires in a certain order No.

(4) Making the wiring diagram of electrical components

The electrical component wiring diagram is made based on the electrical principle of the component and the electrical component placement diagram. It represents the connection and connection of the complete set of equipment and is the basis for electrical equipment, repair and wiring inspection. The wiring diagram should be made according to the following guidelines:

● The production of the wiring diagram and the wiring table should conform to the rules of "Manufacturing of Control System Function Table Diagram" in GB6988.6-1993;

● All electrical components and their leads should be marked with text symbols and wiring numbers consistent with the electrical schematic diagram. The project code, terminal number and wire number in the schematic diagram should be compiled in accordance with GB5094-1985 "Item Code in Electrical Skills" and GB4026-1992 "Electrical Equipment Terminals and Specific Wire End Identification and General Rules for the Use of Alphanumeric Systems" "And GB4884-1985 "Insulated Wire Symbols" and other rules;

● Different from the electrical schematic diagram, the various parts (contacts, coils, etc.) of the same electrical component in the wiring diagram must be drawn together;

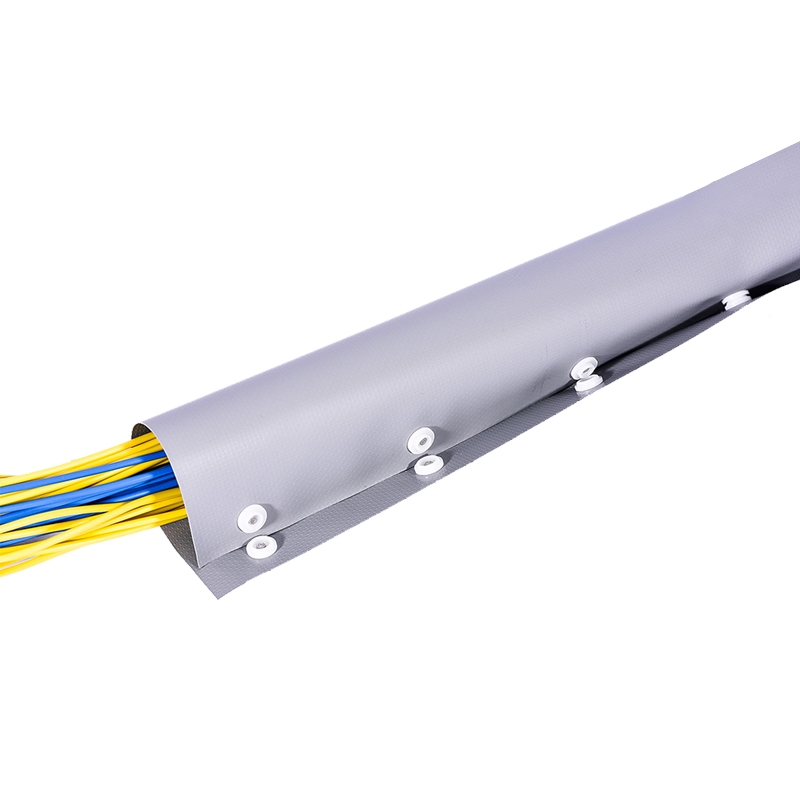

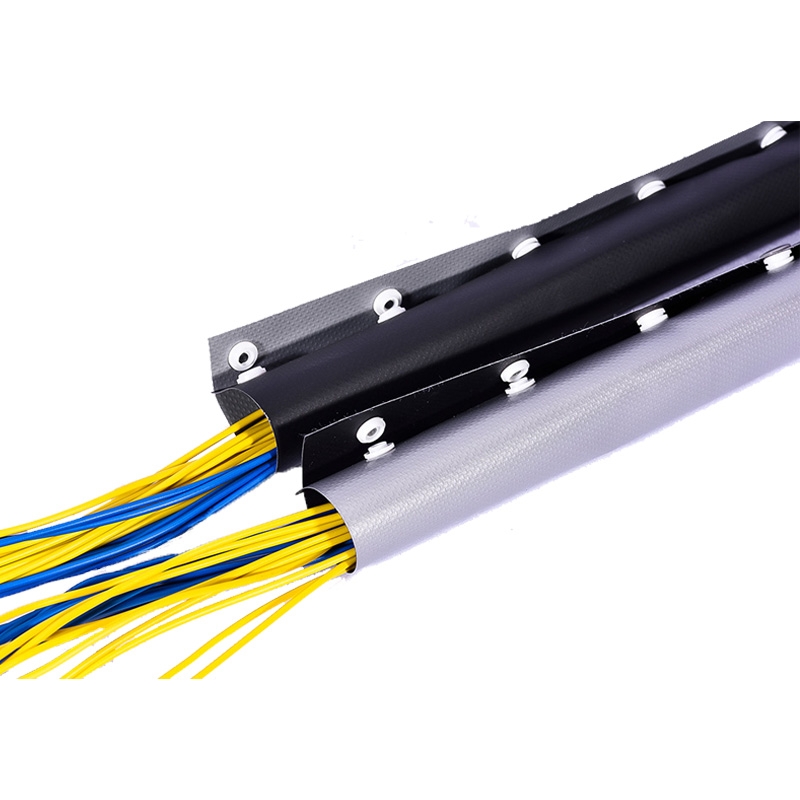

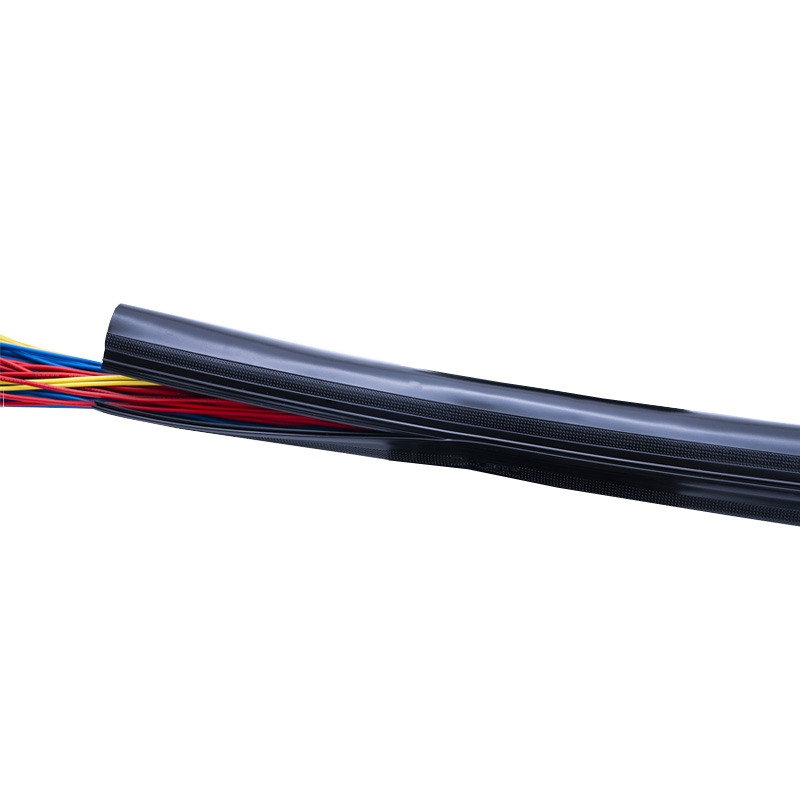

● All electrical wiring diagrams are made of thin lines. The wiring method is divided into two types: the front wiring and the rear wiring. Generally, the front wiring is selected. For simple electrical control components, the number of electrical components is small, and the wiring connection is not messy. You can directly draw the wiring between the components; Regarding the messy parts, the number of electrical components is large and the wiring is messy. Generally, the wiring trough is selected. As long as the wiring number is marked on each electrical component, there is no need to draw the wiring between the components;

● The wiring diagram should indicate the type, specification, cross-sectional area and color requirements of various wires used for wiring;

● When connecting components and external circuits, connectors should be used to connect large cross-section wires in and out, and other connections should be connected to the row via terminals.

(5) Planning of electric control cabinet and non-standard parts drawing

Electrical control equipment generally requires the production of separate electrical control cabinets and boxes, and its planning needs consider the following aspects:

● Determine the overall size and structure of the electrical box and cabinet according to the operating requirements and the size of the various electrical components in the control panel, box, and cabinet. Under non-special conditions, the overall size of the electrical control cabinet should be matched to the basic structure and series;

● According to the overall size and structure of the electrical control cabinet, and the equipment size, plan the equipment support in the box, and mark the equipment holes, equipment bolts and grounding bolt dimensions, and indicate the matching method. The materials of cabinets and boxes should generally use special profiles for cabinets and boxes;

● According to the requirements of on-site equipment orientation, operation and repair convenience, plan the door opening method and type of the electrical control cabinet;

● In order to facilitate the ventilation and heat dissipation of the electrical appliances in the control cabinet, ventilation holes or ventilation slots should be planned in the appropriate parts of the cabinet. If necessary, forced ventilation equipment and ventilation holes should be planned in the upper part of the cabinet;

● In order to facilitate the transportation of the electrical control cabinet, suitable lifting hooks or movable wheels should be planned at the bottom of the cabinet.

For the above requirements, the outline sketch of the electrical control cabinet should be drawn first, the size of each part should be estimated, and then the outline drawing should be drawn according to the share, and then further consideration should be given to adjusting the share of each size from the aspects of symmetry, beauty, and ease of use. After the appearance of the electrical control cabinet is determined, the structural planning of each part of the control cabinet will be carried out according to the above requirements, and the assembly drawings of the cabinet body and the drawings of parts such as doors, control panels, bottom plates, equipment brackets, decorative strips, etc. shall be made, and the processing requirements shall be indicated. Then select the appropriate door lock for the electrical control cabinet according to the needs. Of course, the shape and structure of electrical cabinets are different, and the advantages of various types should be absorbed in the cabinet planning. For non-standard electrical equipment parts, parts drawings shall be made according to the planning requirements of mechanical parts. The requirements for public service shall be indicated in the cooperation scale, and the processing requirements shall be clarified.

Then, according to various drawings, the various parts and data required by the electrical control cabinet are summarized and calculated, and the summary list of purchased finished parts, the list of specifications, the main data consumption quota and auxiliary data are listed by category. The quota table, etc., so that the purchasing personnel and the production management department can prepare materials according to the equipment production requirements, prepare for production, and facilitate cost accounting.

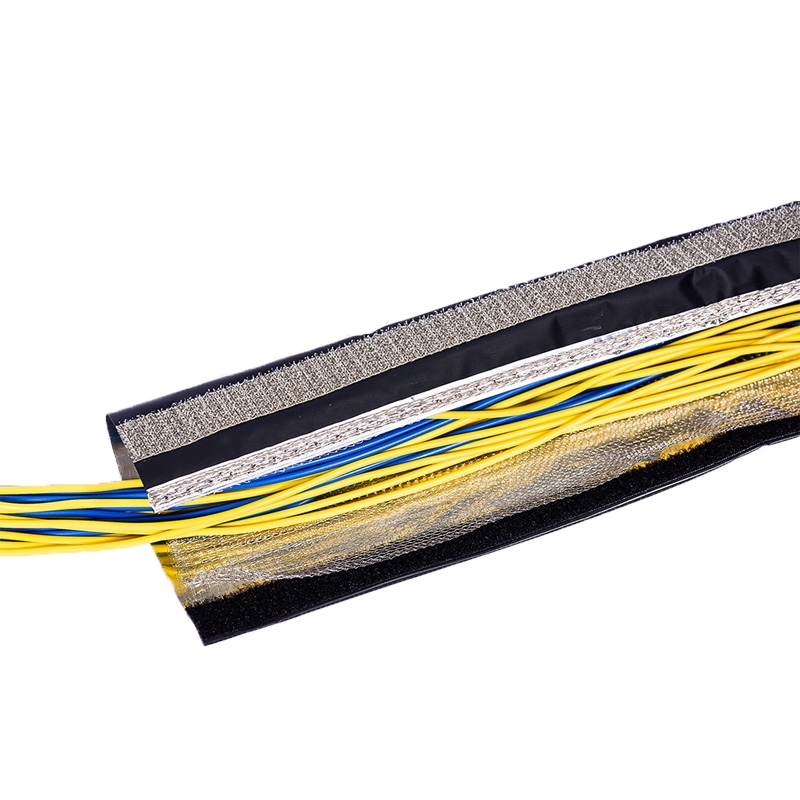

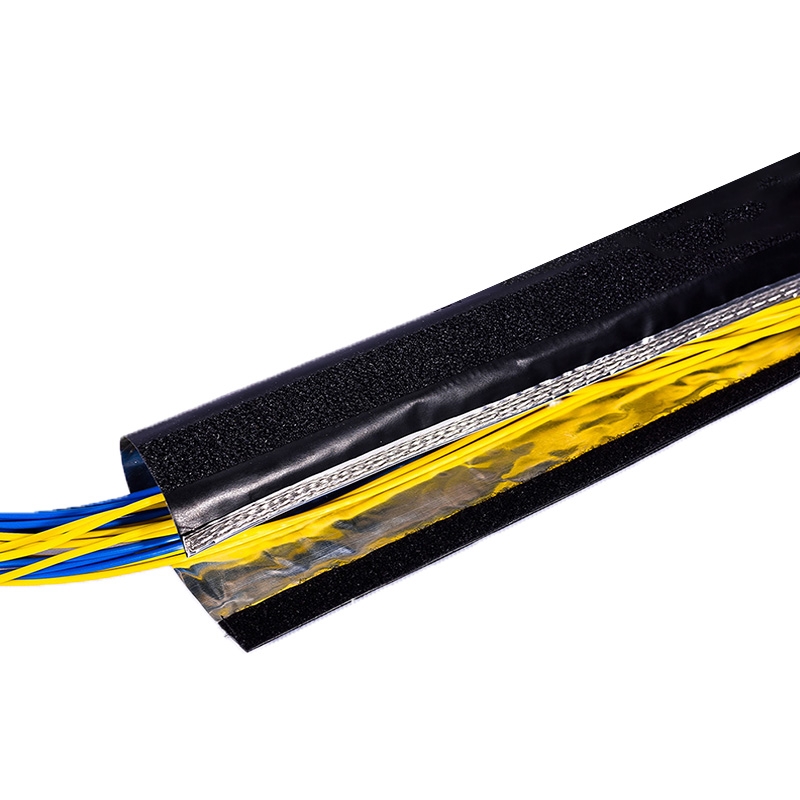

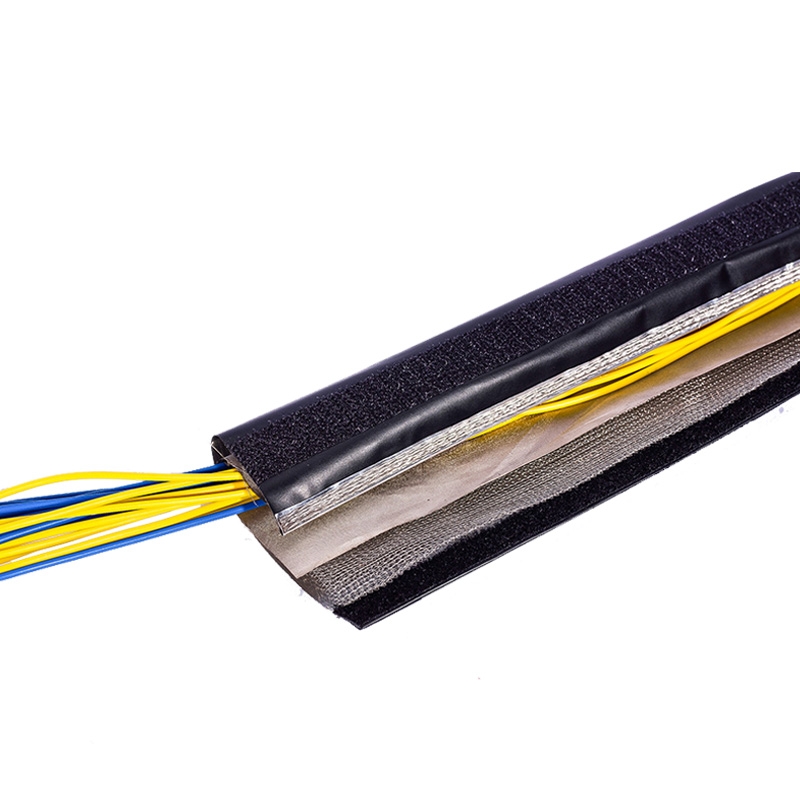

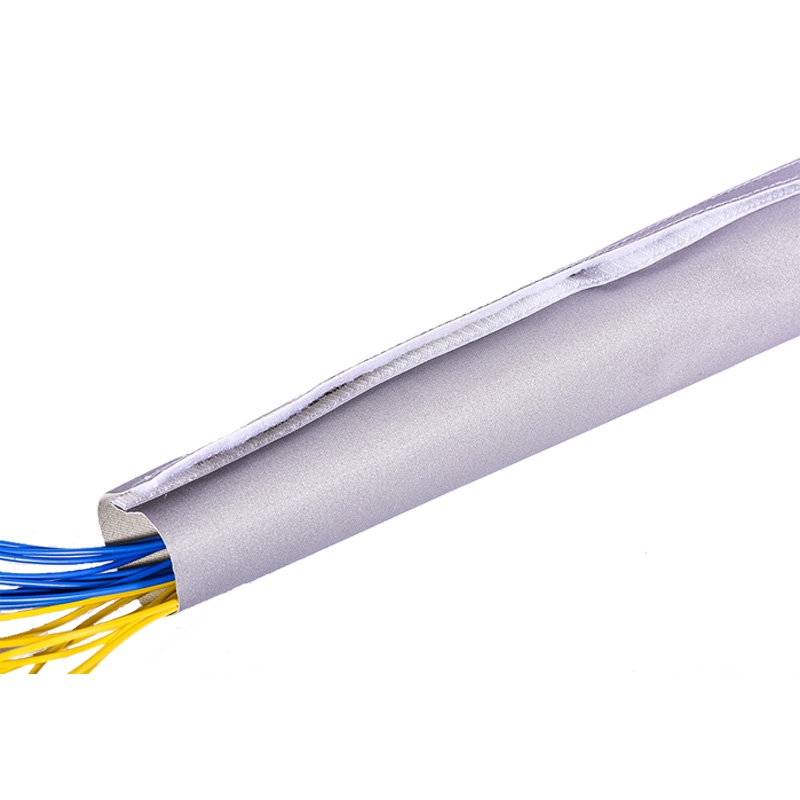

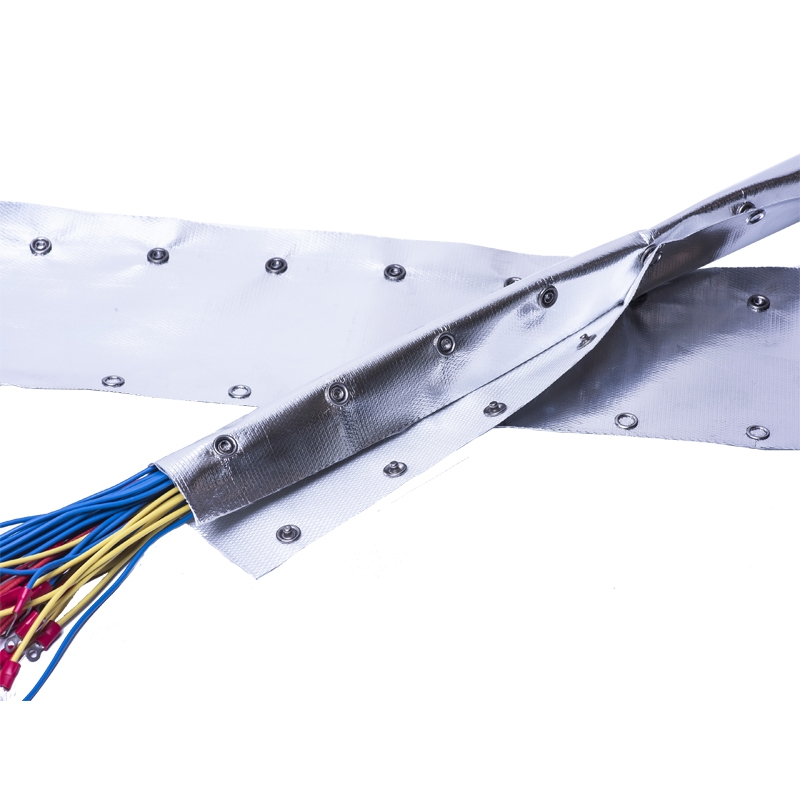

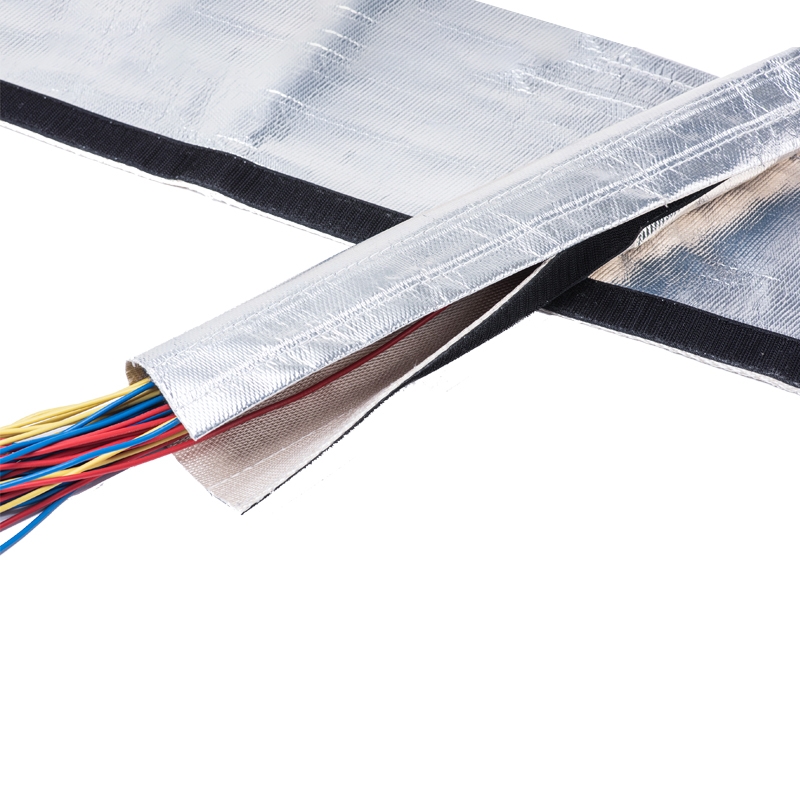

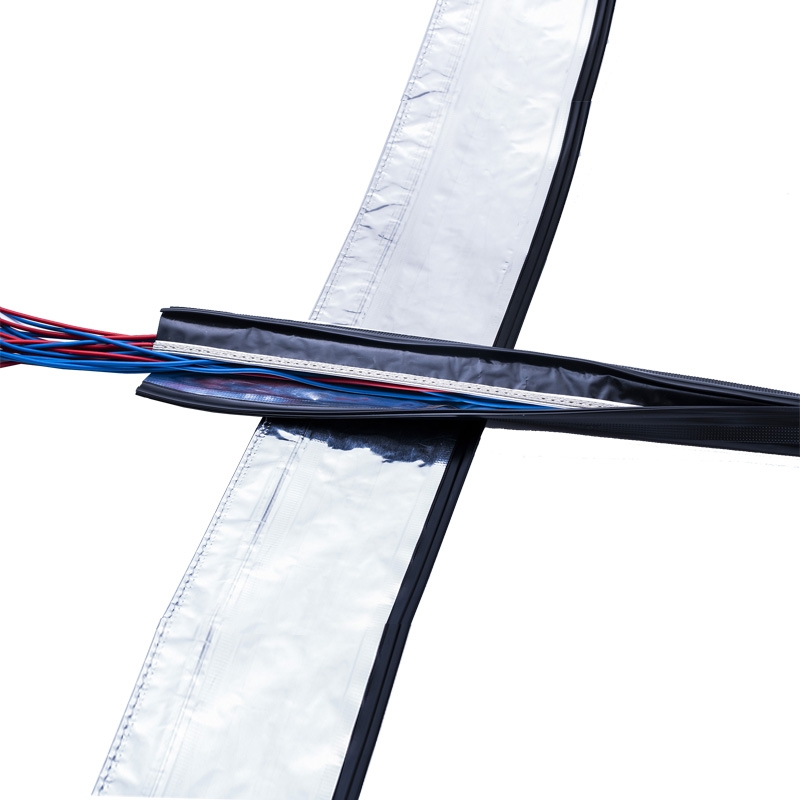

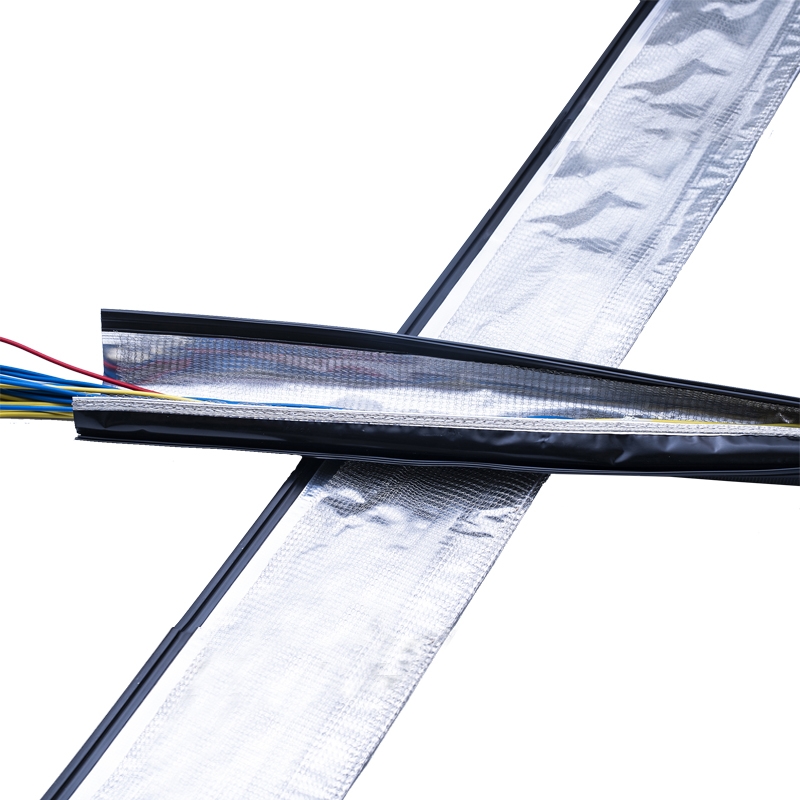

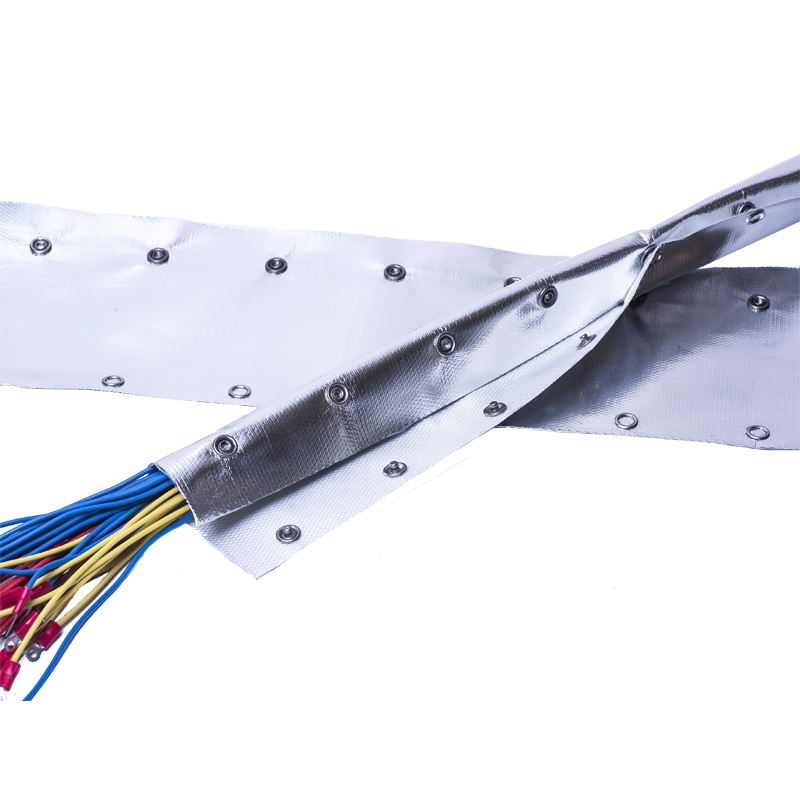

Buckle end belt