Explosion-proof and fire-proof necessity of cable joints

Release Date:2021-04-30 Author: Click:

Because of the requirements of urban development planning, more and more cable tunnels are used, which brings greater convenience to people. However, there are also many problems. Among them, the blasting of the cable joints causes the fire in the cable tunnel to be a serious problem. There have been many cases of fire incidents in tunnels caused by blasting of cable joints in the whole country. Because of the narrow space in underground tunnels, many obstacles, messy combustible materials inside the cables (messy insulation materials), dense cables, and poor ventilation, high temperature and dense smoke (hcl, co) are easy to accumulate after a cable fires, and a lot of harmful gases will be released. The rescue operation brought great difficulty, and then a large area of cable damage was formed. In the following, only the necessity of temperature measurement of power cable joints in cable tunnels and the explosion-proof and rescue of cable central joints will be discussed.

1. Cause analysis and characteristics of cable fire in the tunnel

The causes of fire in the tunnel can be divided into two categories: one is the fire caused by an external fire source, because the cable tunnel is closed and isolated from the outside, this possibility is relatively small. The other type is fire incidents caused by cable faults. This type of incident is more likely to occur. Among them, there are more faults caused by cable connector faults. According to statistics, it accounts for 70% of the total cable incidents. The reason is that the cable center The joint manufacturing process is rough, the manufacturing quality is poor, the crimping joint is not tight, the touch resistance is too large, the cable insulation or the cable core is damp, etc., during long-term operation, the temperature of the cable center joint will increase until overheating burns through the insulation, which will eventually lead to buckle The blasting of the type casing cable joint produced an electric arc, which caused a fire.

The temperature of the faulty point of the cable joint changes slowly from low to high, which means that the faulty point will not change suddenly. According to the analysis, if we install an optical fiber temperature measurement system at the central joint of the cable, it can be accurately monitored in time. As far as the operating temperature parameters of the cable are concerned, when the temperature of the cable is abnormal, we can find out the danger in time and deal with it in time. If the cable center connector is equipped with an explosion-proof box and an active rescue system, when the cable is blasted, other cables will not be injured due to the blasting of the cable center connector. At the same time, the active rescue system will be actively activated to control the flame extension and make The problem will not expand further, and the loss will be reduced to a low level.

Regardless of the cause of the fire in the cable tunnel, the cable has the characteristics of fast extension, fierce fire, difficult to rescue, difficult to repair, and severe loss after a fire, so it is necessary to attract our attention.

The cable center joint is a kind of explosive, and there are 10KV and 110KV cables laid in the same tunnel in the tunnel. The cables are densely distributed in the tunnel. Multi-layer cables or cables are cross-stacked. When a fire occurs, the cables will be burnt in three dimensions, plus a cable shaft. The height difference forms a natural draft, which causes airflow in the tunnel. In addition, the heat released during incineration is not easy to dissipate, and the temperature in the tunnel rises. Therefore, once a fire occurs in the tunnel, the fire develops particularly rapidly, and the fire will spread quickly. A large amount of smoke and toxic gases (such as hcl, Co, etc.) will be generated when the cable is on fire. In addition, the narrow area in the tunnel makes it difficult for a large amount of smoke to be discharged. It prevents repair personnel from entering the tunnel immediately for repairs, prolonging the time of power outage, and the loss caused by the cable fire incident is very serious. At the same time, cable fires are also particularly dangerous, that is, if the secondary control loop fails, it is easy to cause the expansion of incidents, such as damage to the main equipment of the power grid, skipping trips, etc., making it difficult to repair the equipment or causing a large-scale power outage.

2. Cable joint temperature monitoring, active rescue system and cable joint explosion-proof box

The optical fiber temperature measurement system and active rescue system of the cable center joint refer to the cable design specification, and use electronic skills and active control skills to enable the cable to perform 24-hour online monitoring of the cable center joint under the control of a high-performance industrial control computer. Graphic display, sound and light alarm, etc. provide the operating temperature parameters of the cable center connector and the specific location of the fault hazard, so that the cable maintenance personnel can take measures in time and take precautions. Because the cable connector is equipped with an explosion-proof box, even if the cable center connector blasts, it will not damage other cables. At the same time, the active rescue system will actively put into operation, extinguish the flame, reduce the loss to a lower level, and then completely solve the cable The chain fire incident caused by the overheating of the central joint ensures the safe operation of the power grid and improves the production power and economic benefits of the power grid.

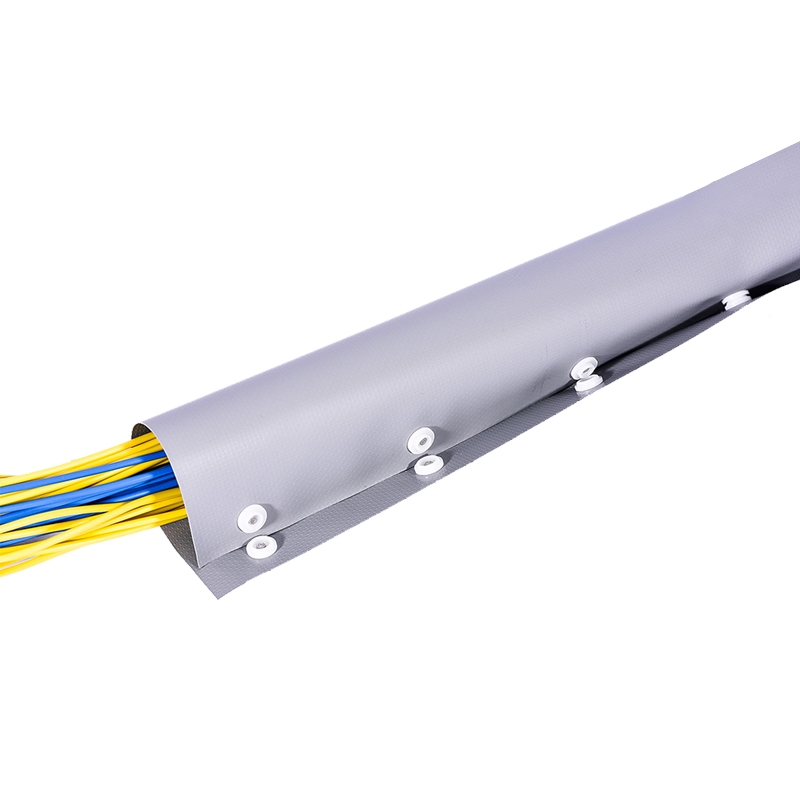

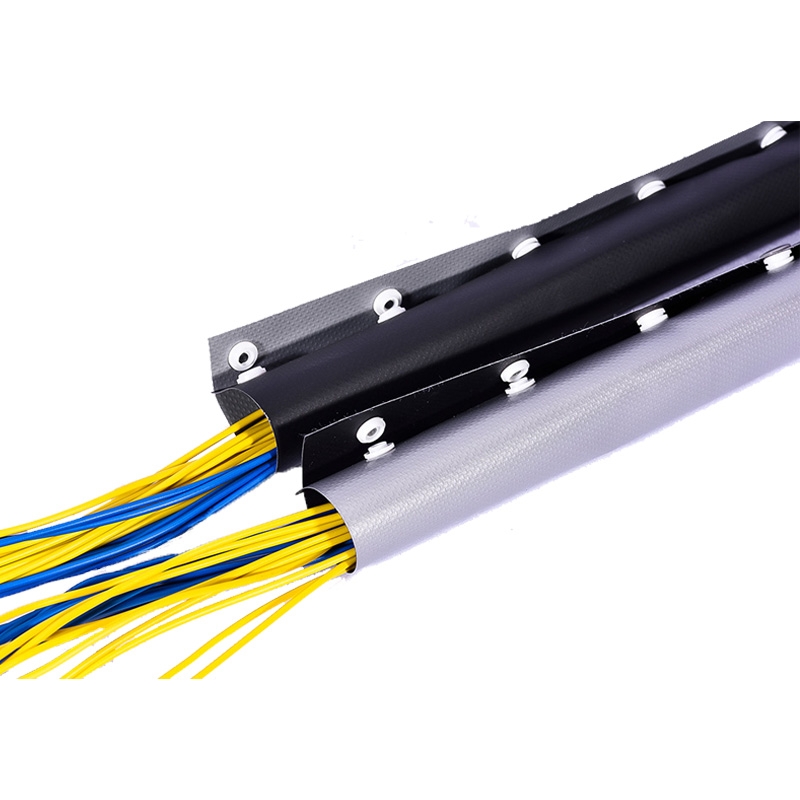

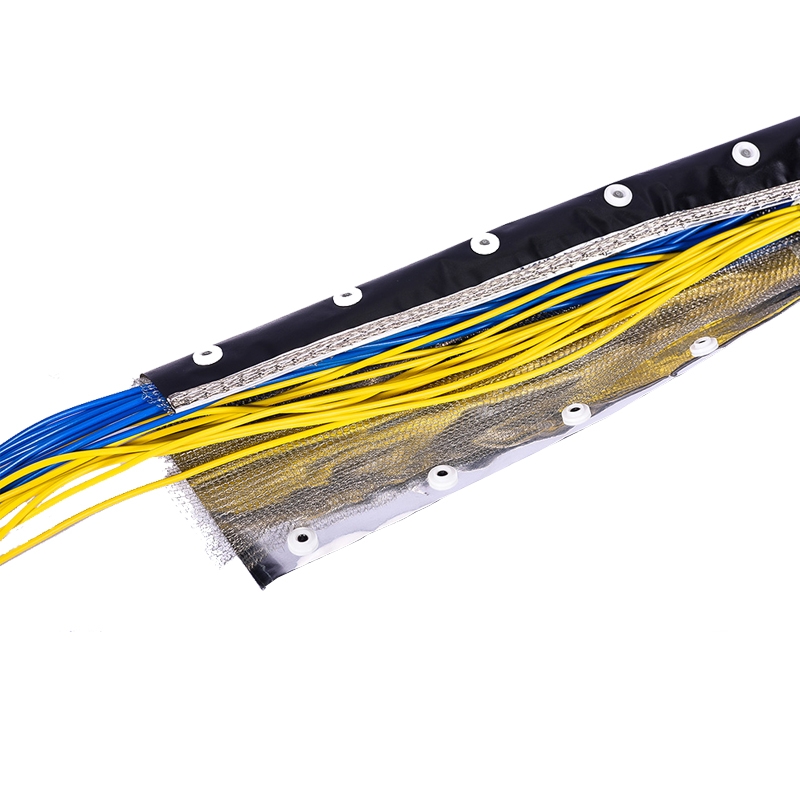

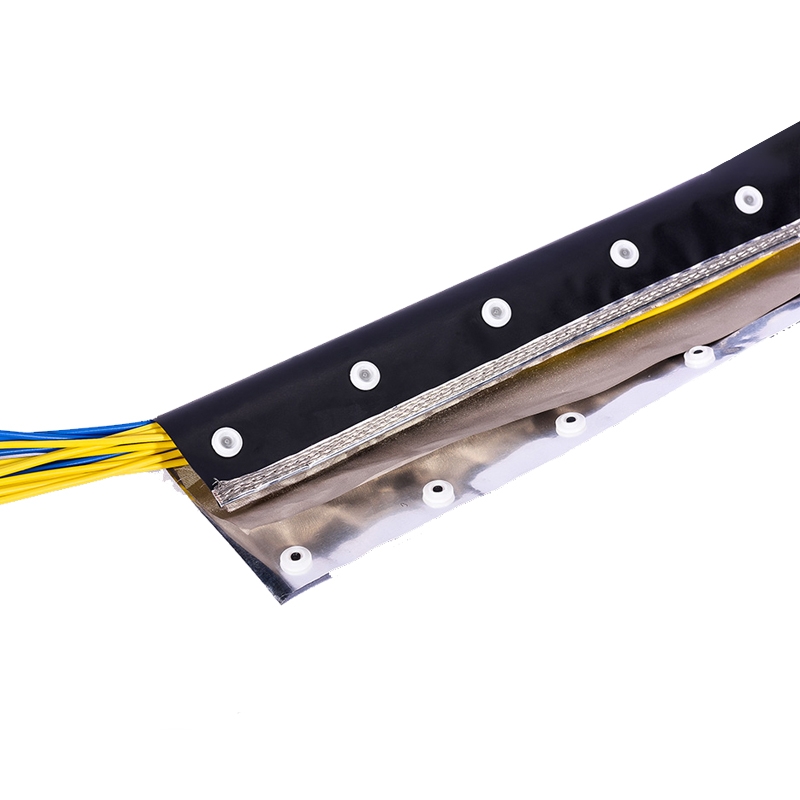

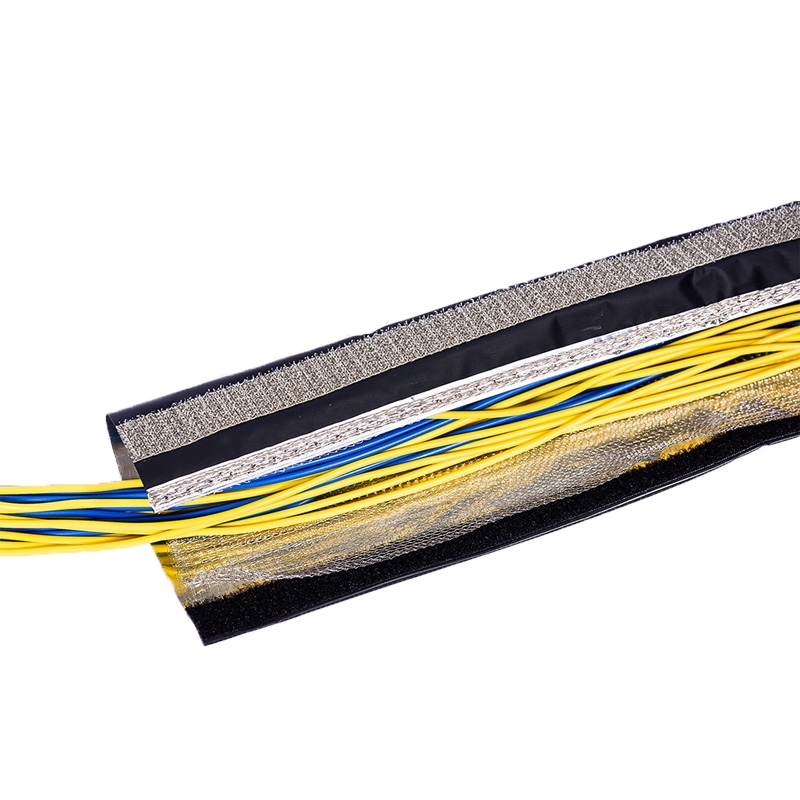

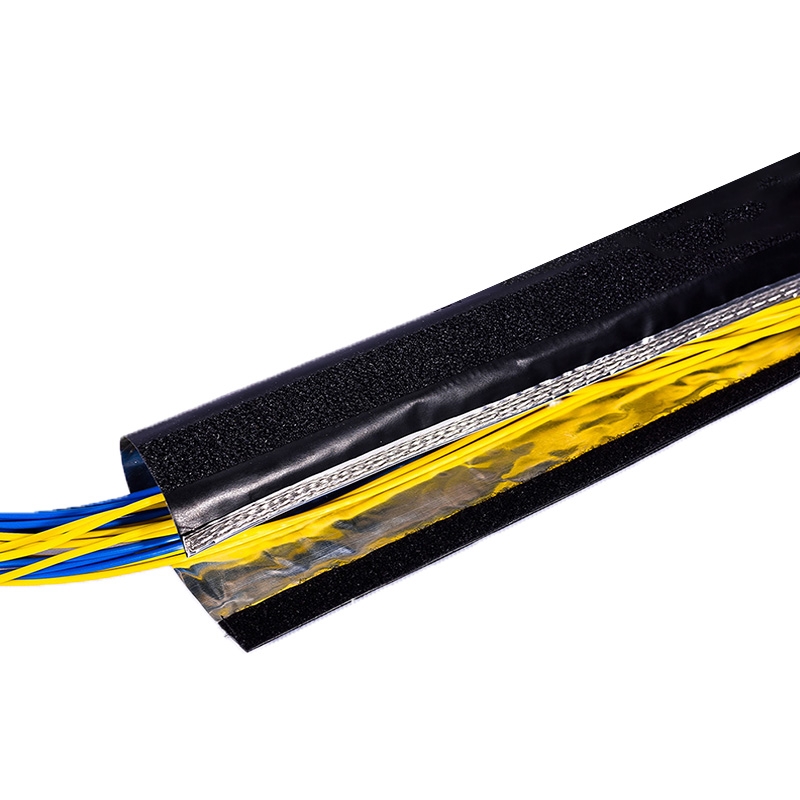

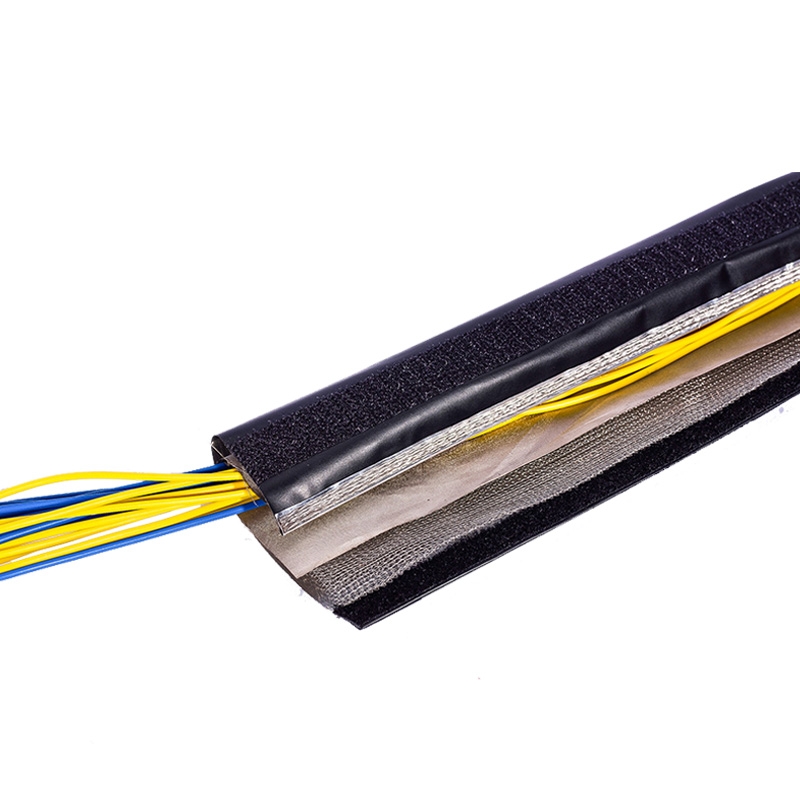

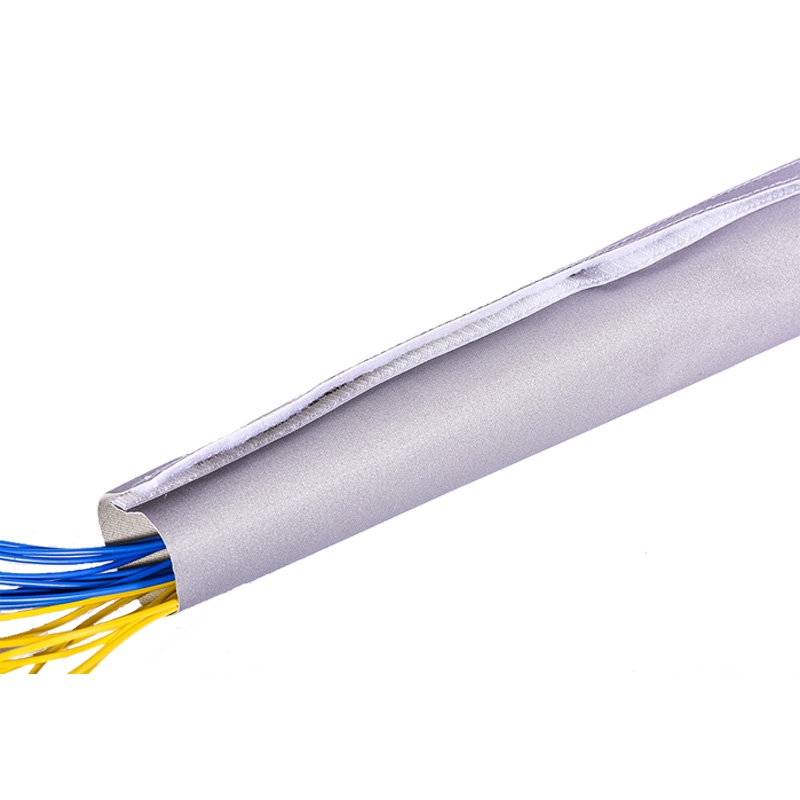

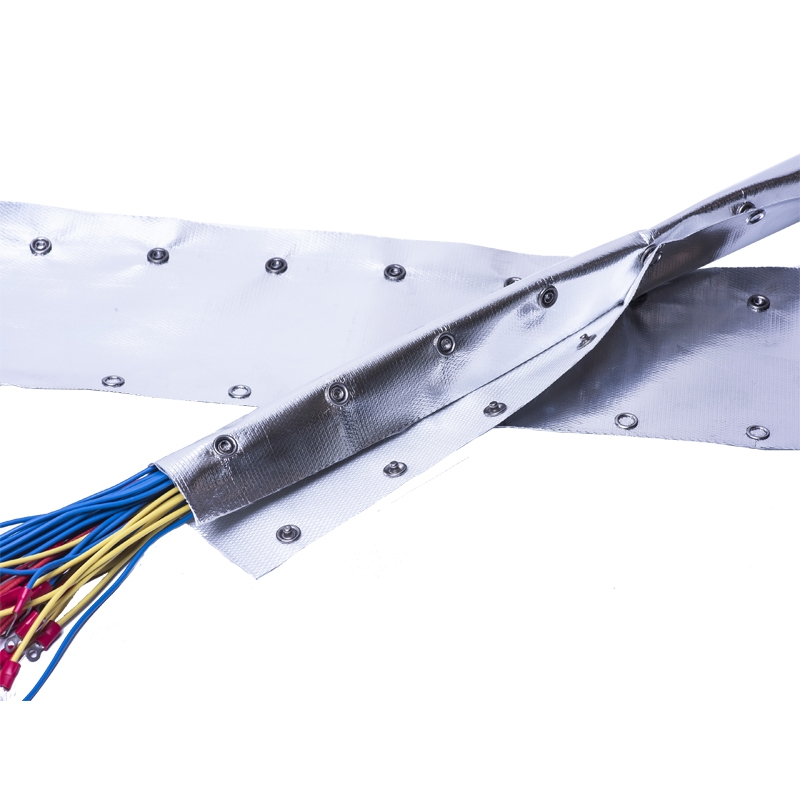

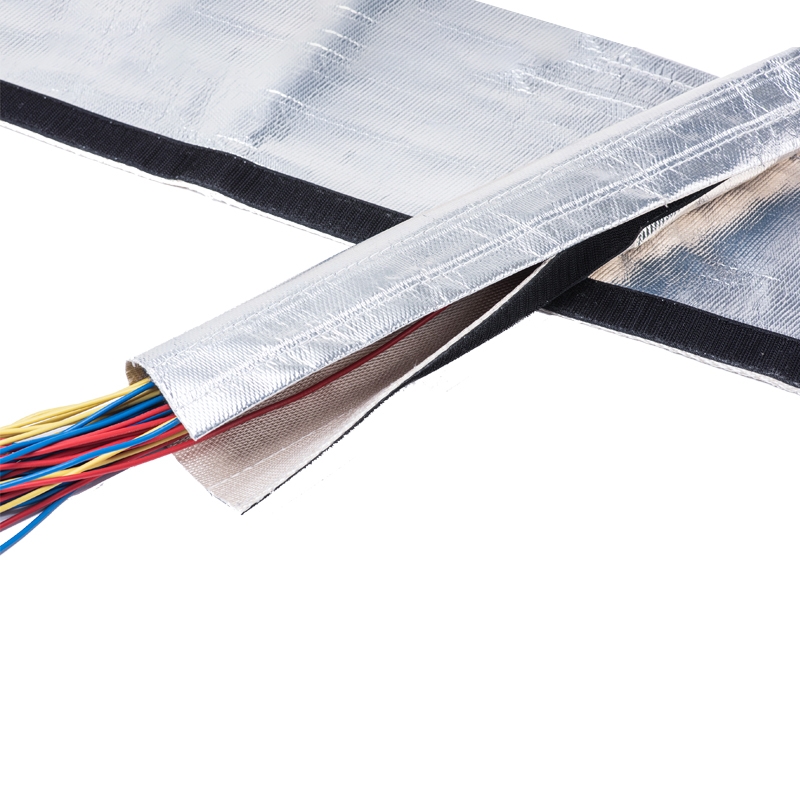

There are conductor resistance and touch resistance at the pressure receiving place of the cable center connector. When the current passes through the cable center connector, it consumes energy and generates heat. Under normal circumstances, the touch resistance is very small, and the temperature rise caused by the resistance is within the normal range. When the cable center connector is badly touched, the touch resistance will increase (such as: the crimping is not tight, the cable core is damp and oxidized, etc.), and then caused The center joint heats up and the temperature rises. When the temperature rises beyond the normal value, it will cause the oxidation of the cable core and the loosening of the crimping. This vicious circle will eventually lead to the destruction of the cable insulation and the explosion of the cable joint. In order to avoid the blasting of the cable joint, the arc after the blasting will cause fire and damage other cables. Therefore, it is necessary to install the cable joint temperature monitoring and active rescue system in the tunnel. The cable joint is equipped with an explosion-proof box, and then the cable center joint can be found early The existing problems enable our buckle-type casing repair personnel to deal with them in time, and then avoid the occurrence of incidents. Even if the problem occurs, the loss can be reduced to a small amount.

The optical fiber temperature measurement system and active rescue system of cable joints have the following characteristics:

1. The optical fiber temperature measurement system can accurately monitor the operating temperature parameters of the cable, and accurately locate the faults of the cable joints in operation; monitor the temperature changes of the cable joints in the tunnel in real time, and the system will actively alarm when the temperature exceeds the set value;

2. The active rescue system takes the initiative to rescue when a fire is generated by the blasting of the cable center joint.

3. The system is mainly composed of several parts such as a central control system, a temperature measurement terminal, an alarm terminal, and an active rescue system:

(1) The central control center collects and stores the monitoring information of each monitoring point, which is convenient for inspectors to inquire about the operating temperature status of the cable joints;

(2) The temperature measurement terminal adopts advanced technology to ensure the accurate and reliable collection of cable joint temperature data, and it is suitable for multi-point simultaneous monitoring;

(3) The alarm terminal adopts advanced technology. When the temperature of the joint exceeds the set value, it can alarm in time and accurately, so that the repairer can eliminate the danger of faults in time;

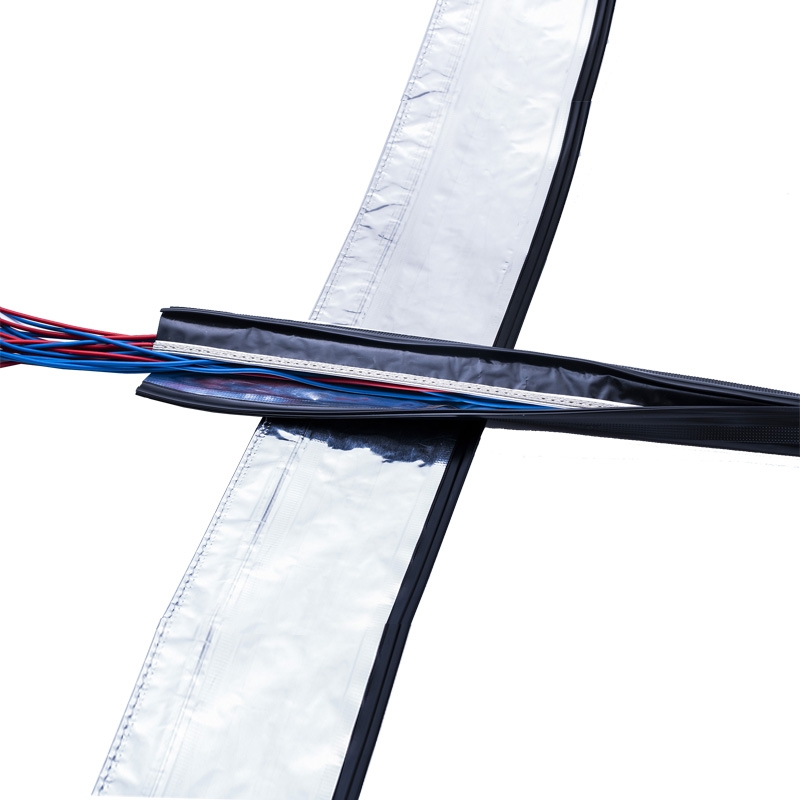

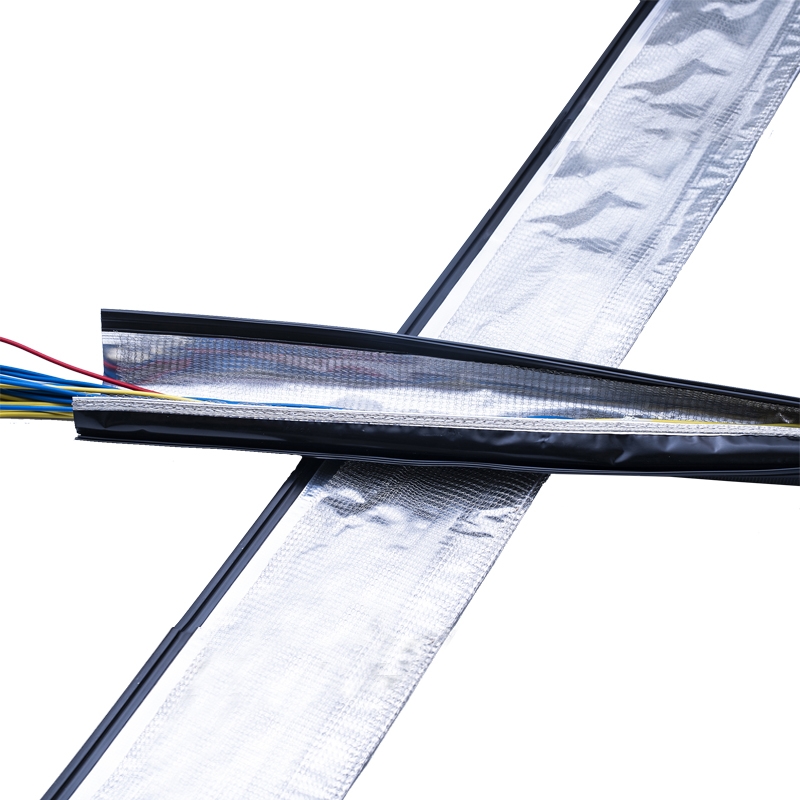

(4) The active rescue system uses ultra-fine dry powder with outstanding rescue activity and environmental reliability. The active rescue system uses a suspension structure and nitrogen drive. It can be achieved by only hanging the equipment above the maintenance object. The two-layer function of total submergence and partial maintenance. If the cable center joint generates high temperature and causes the joint blasting to produce flames, it will actively spray out the rescue flame retardant powder to extinguish the live seedlings. In recent years, fire incidents in domestic cable tunnels have occurred from time to time. The cause of the fire is mainly caused by the overheating and blasting of the cable center joint and the generation of electric arcs. The resulting loss is very serious. In order to ensure the safe and economical operation of cable equipment and systems, it is necessary for the cable central joint in the tunnel to be equipped with a central joint explosion-proof box. The device cable central joint explosion-proof box can safely avoid the cable tunnel fire caused by the blasting of the cable central joint, and it has the advantages of not changing the structure of the cable joint and convenient installation. The explosion-proof box is composed of an outer shell and a fire-resistant obstructive combustible material, which can completely prevent the cable central joint from producing faults and causing the arc to damage other cables when blasting. Coupled with the use of optical fiber temperature measurement system and active rescue system, fires in the cable tunnel can be completely avoided.