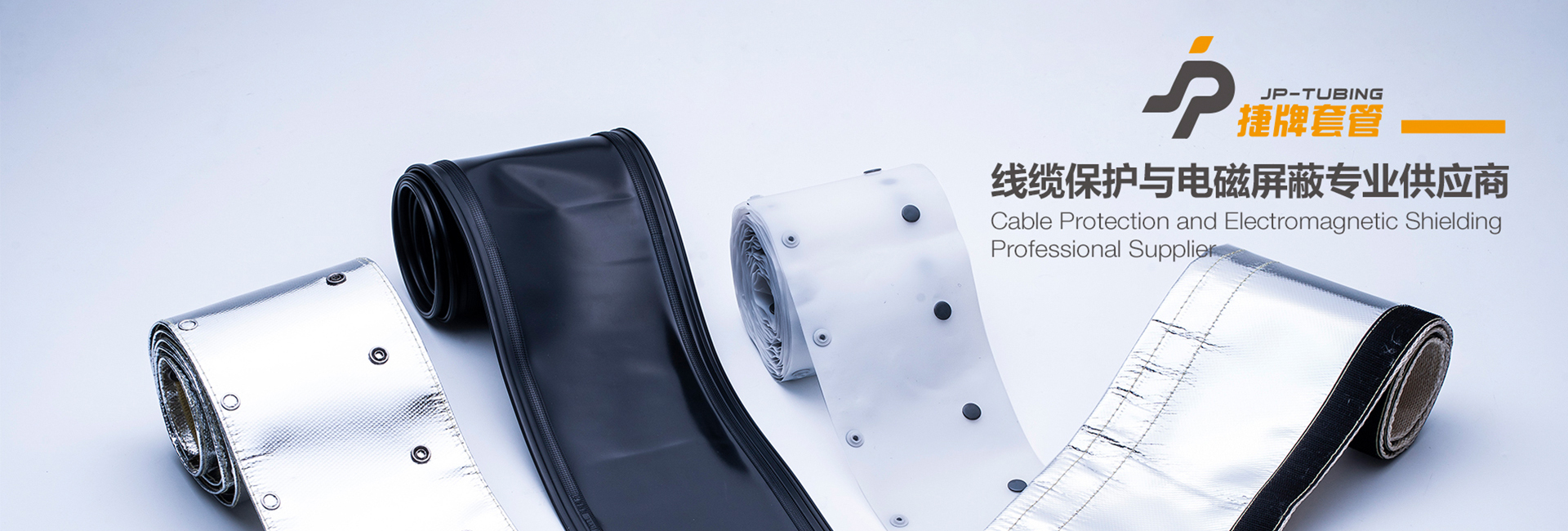

Application of anti-wave sleeve

Release Date:2021-05-10 Author:admin Click:

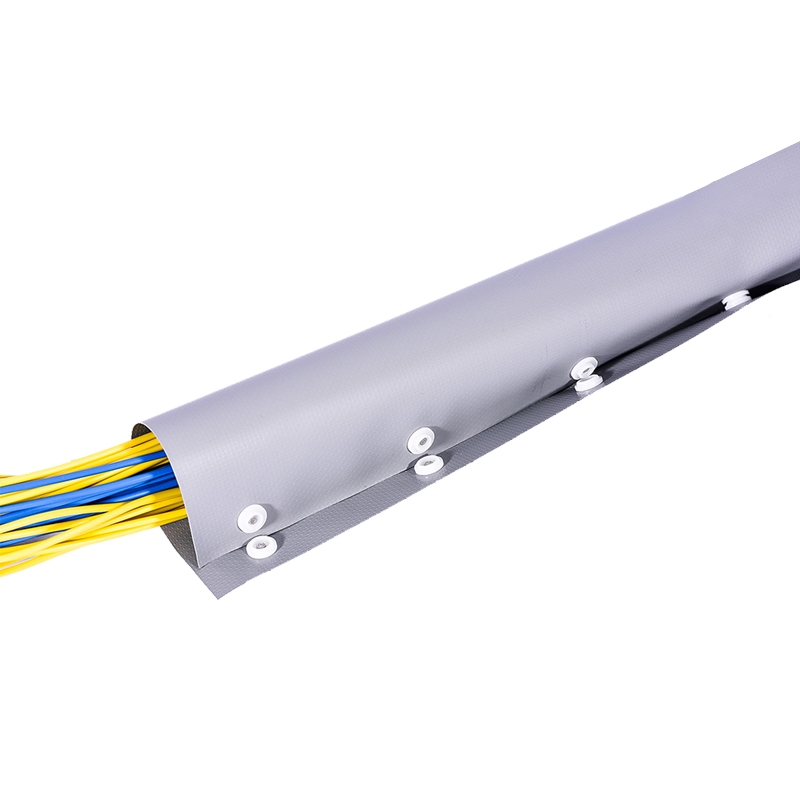

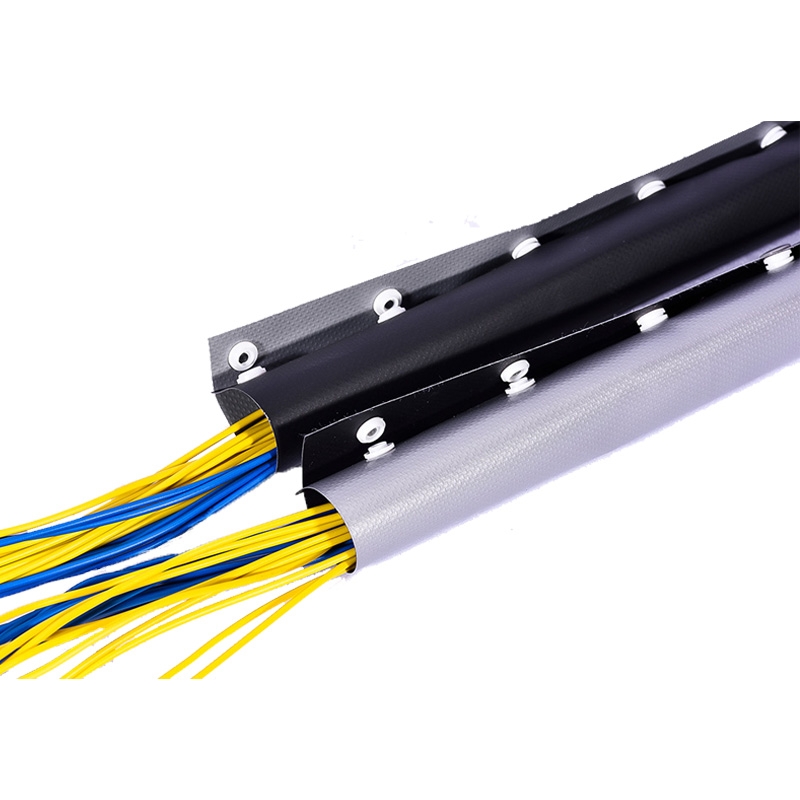

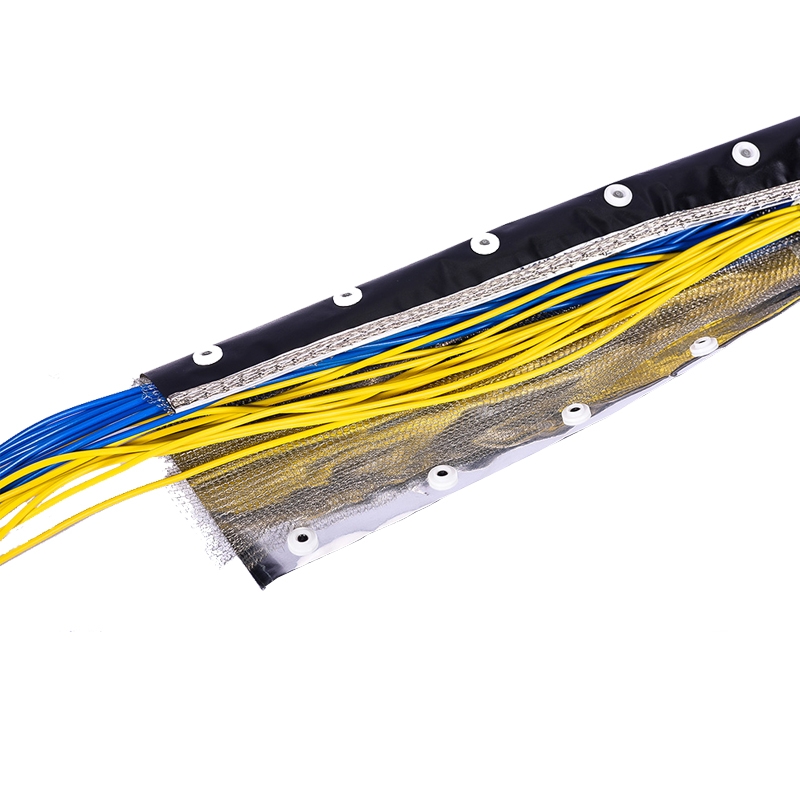

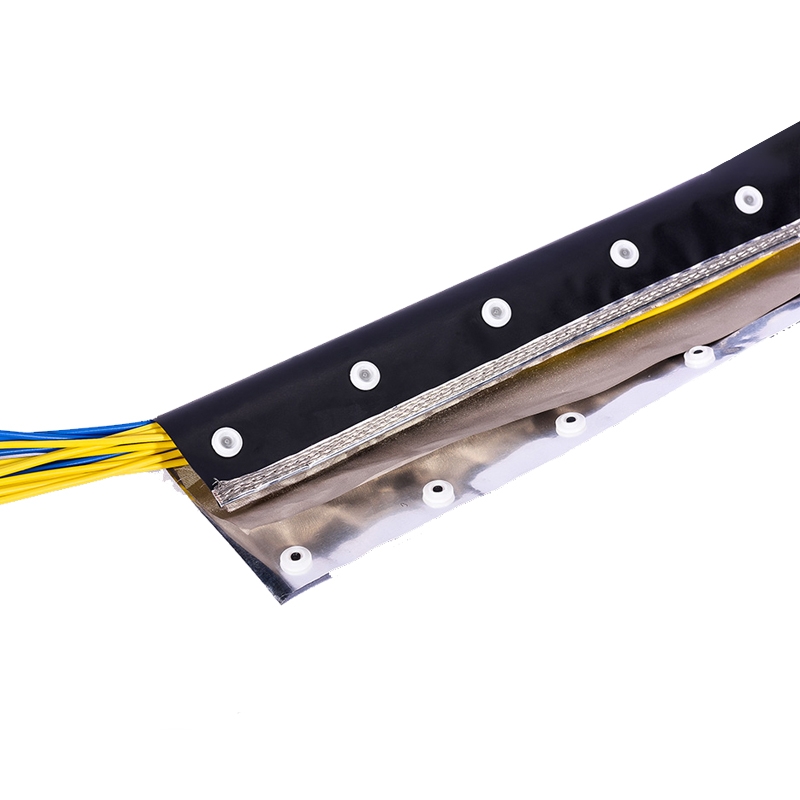

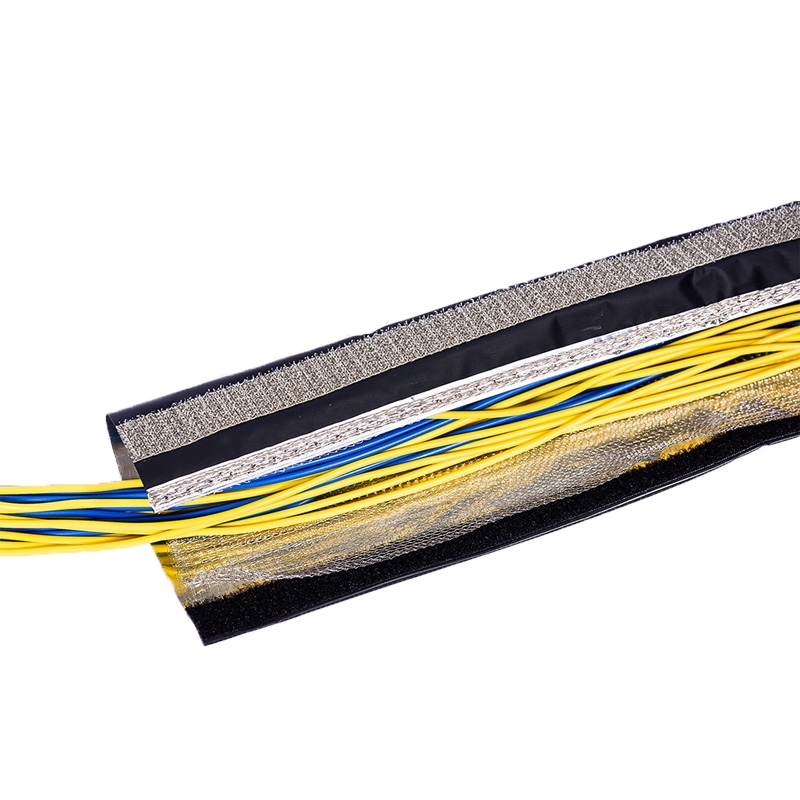

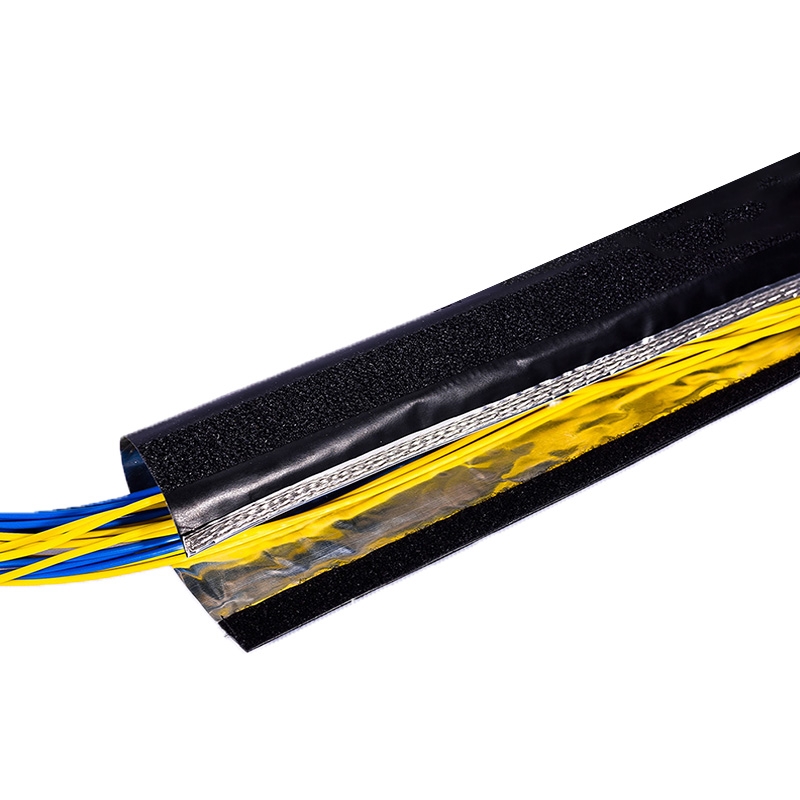

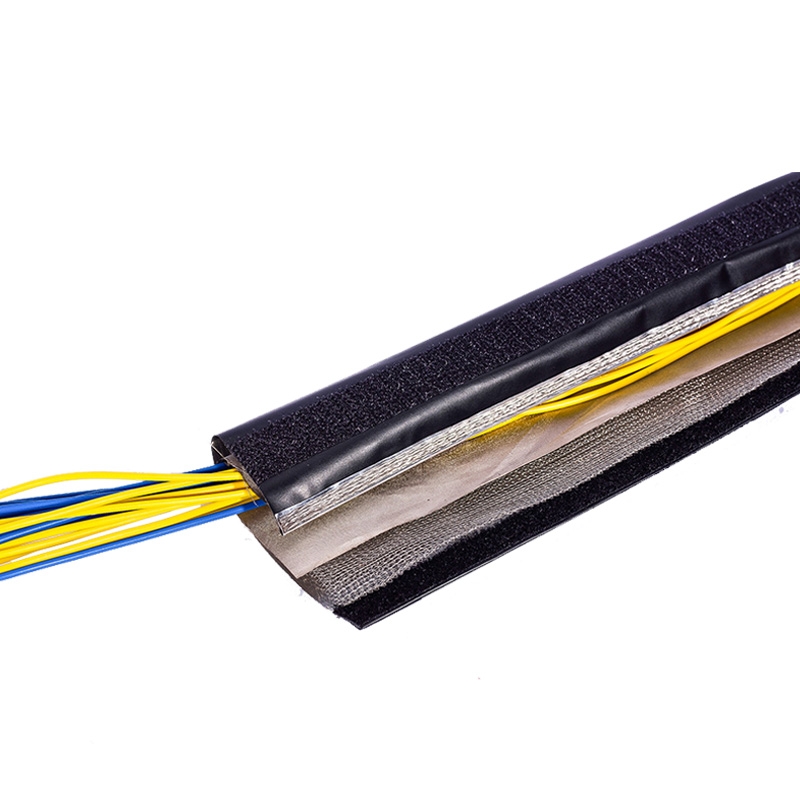

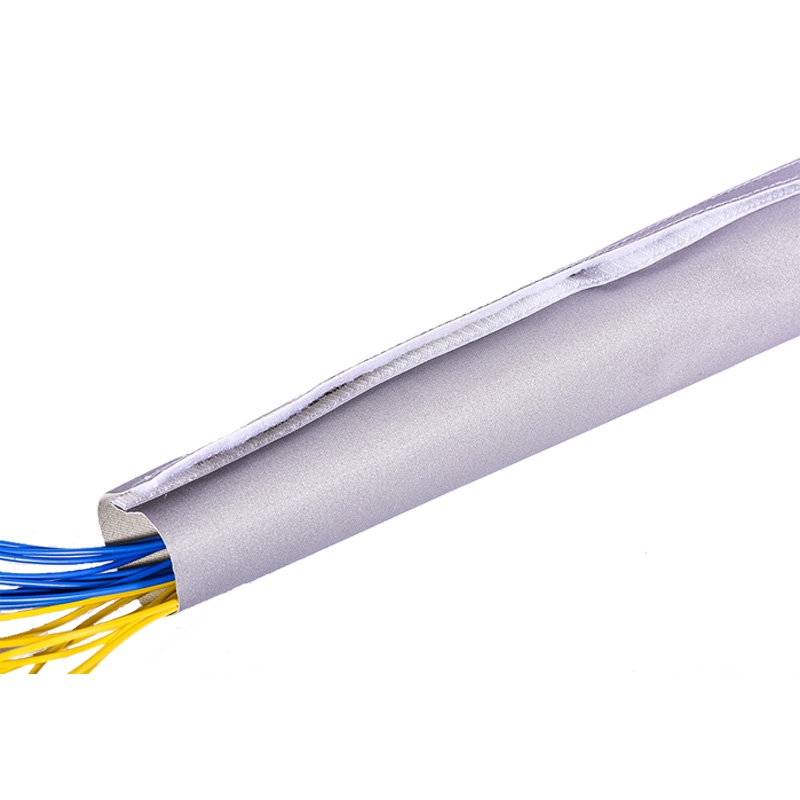

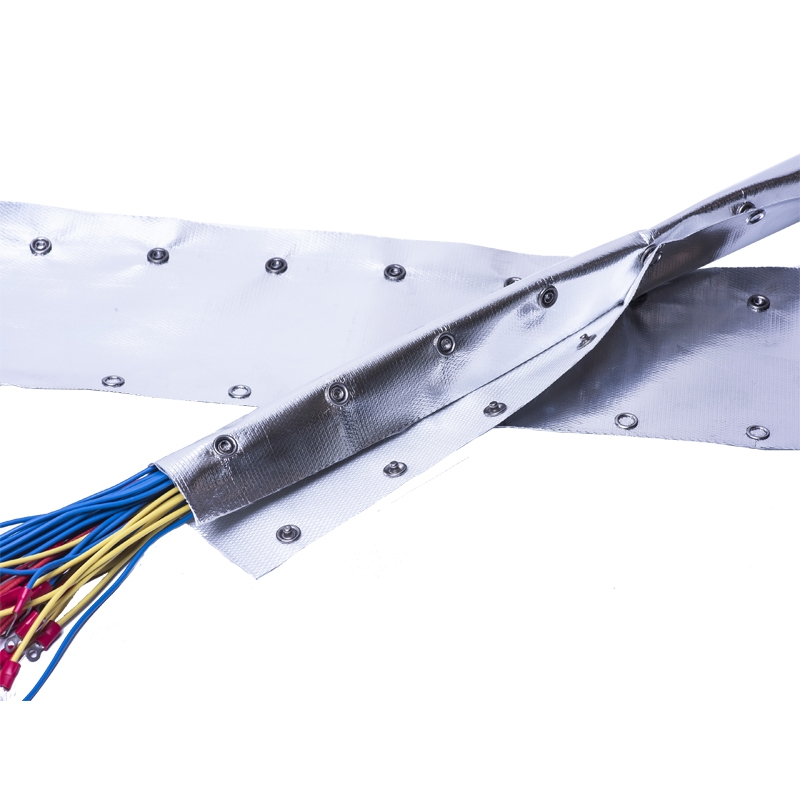

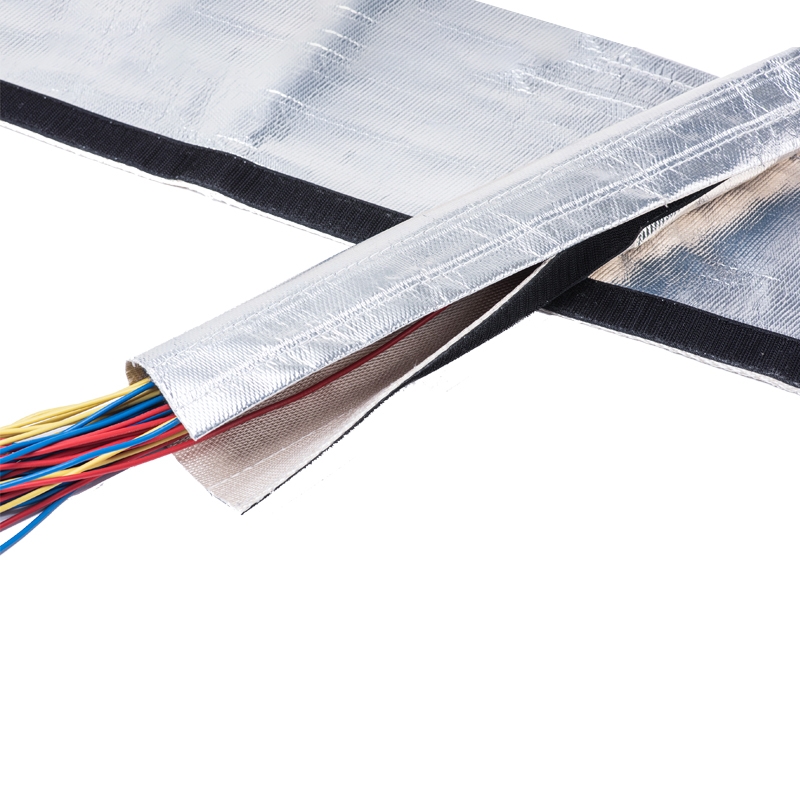

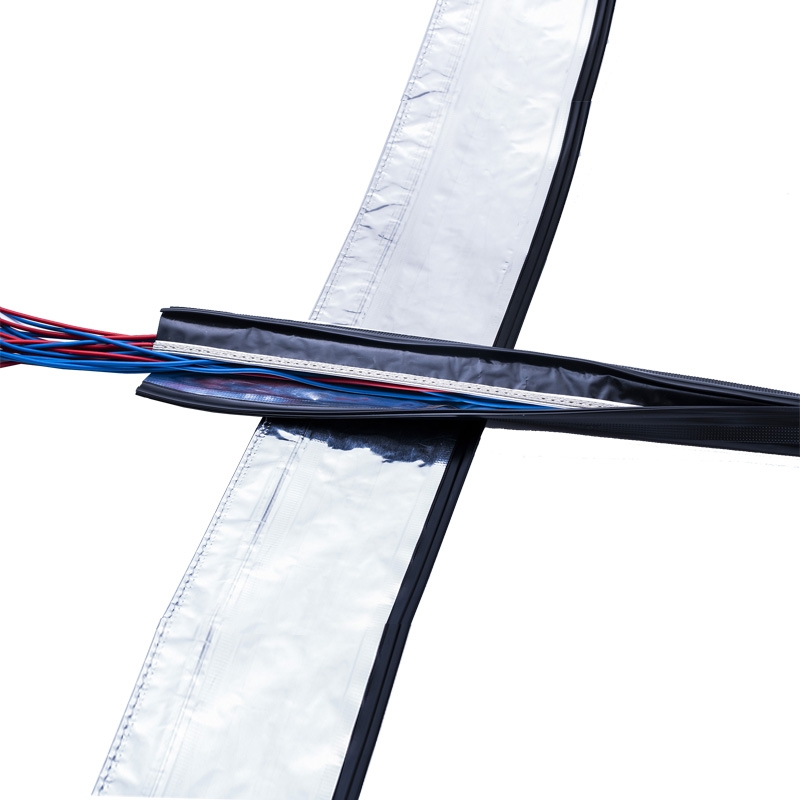

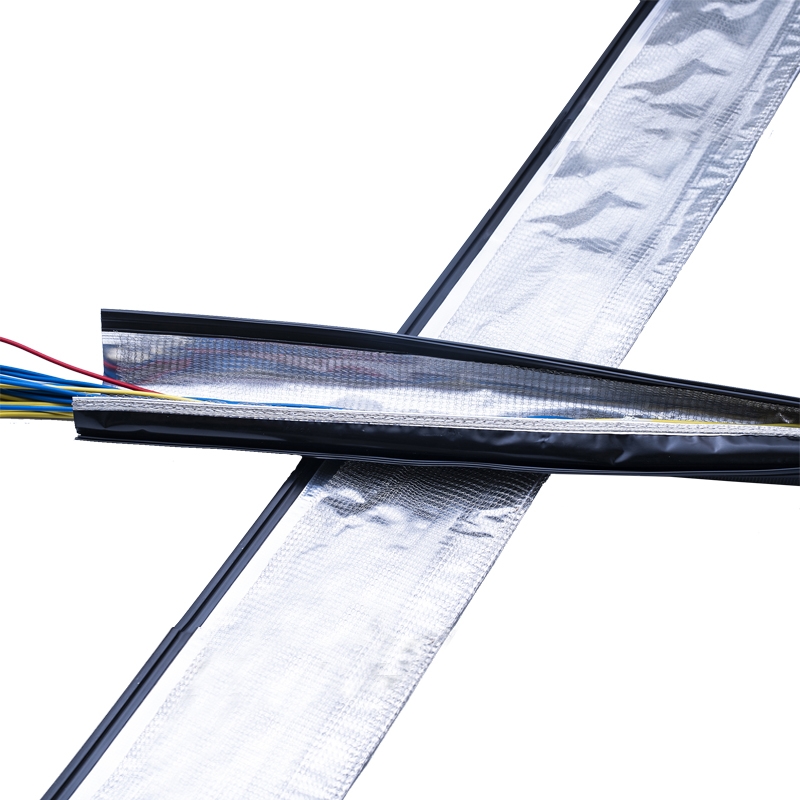

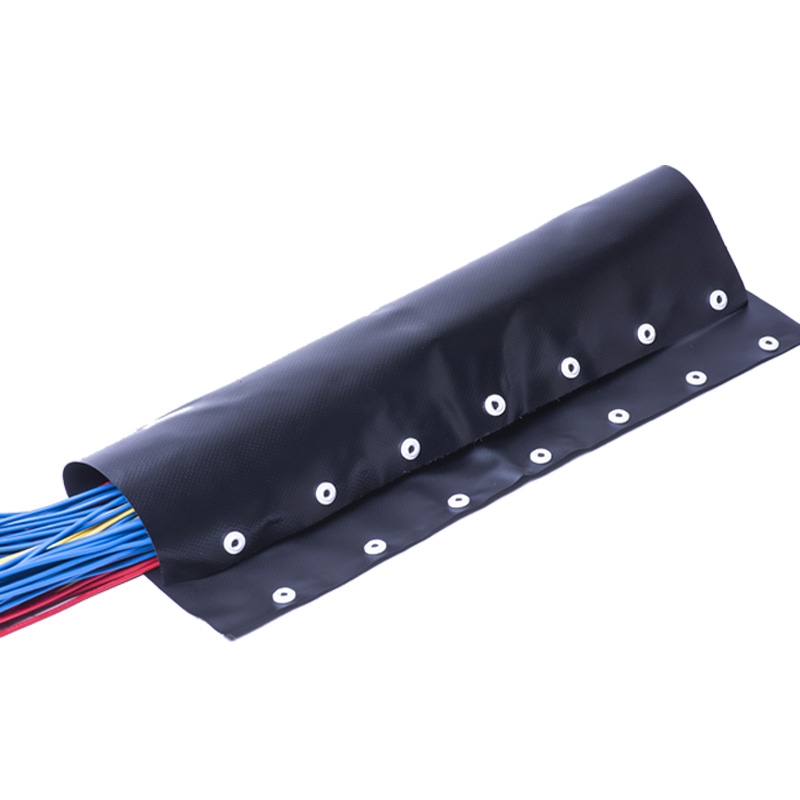

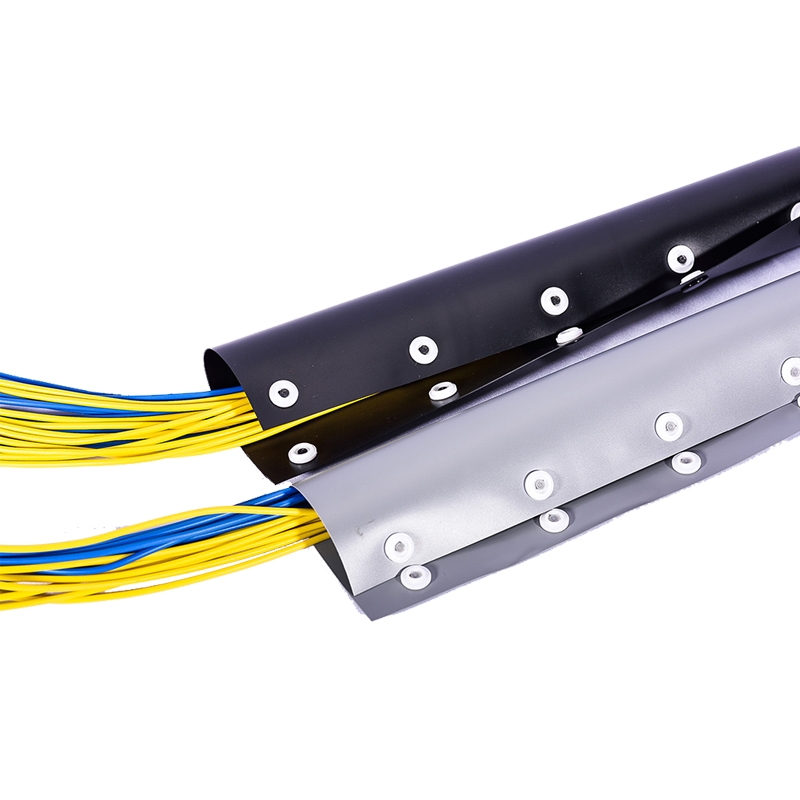

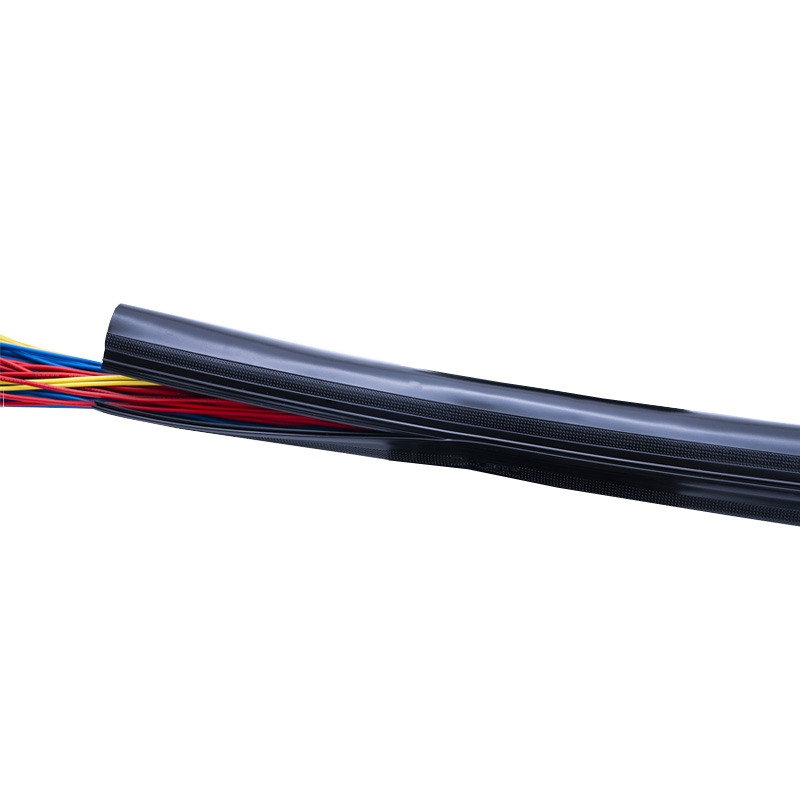

Shielding sleeve, also known as anti-wave sleeve. The special light anti-wave sleeve is a mesh buckle sleeve product used for shielding electromagnetic effects of various conductive currents. In the aviation system, it mainly plays the role of anti-wave shielding of the power system cable harness, that is, preventing the interference of external electromagnetic waves to the wiring harness and maintaining the power The normal operation of the system. In this regard, the shielding function of new products is mainly reflected in the product weaving density. The higher the density, the better the anti-wave shielding function, and vice versa.

Structure: bare copper (BC) tin-plated, nickel-plated, silver-plated copper woven wireUses: power tools, motors, switch tubes, instrument line frequency, anti-wave sleeves, speaker voice coil cables, shielded wires, household appliances, electronics Equipment, lighting fixtures, temperature sensors, etc. lead out connecting lines

Products are widely used in high and low voltage electrical appliances, vacuum electrical appliances, high and low voltage switch cabinets, electric welding machines, automobiles, electric locomotives, electric furnaces, mining explosion-proof electrical appliances, generator sets, carbon brush wires.

The standard of tinned anti-wave cover for copper weaving wire can be customized: Features: A Weaving method: 8 weaving, 12 weaving, 13 weaving, 16 weaving, 24 weaving, 32 weaving, 36 weaving, 40 weaving, 48 weaving, 64 weaving, 72 weaving , 96 braid, etc., commonly used standard for wire diameter; 0.05mm-0.20mm, tight weaving layer, beautiful color, good wear resistance, tensile resistance, temperature resistance, cold resistance, good wire flexibility, easy peeling, easy tinning , Strong tensile force, good insulation, low resistance and strong conductivity. The standard can be changed according to customer requirements (special products such as more than 10 single strands).

At present, the similar products of button casing are mainly made of pure metal wire weaving, and their strength, high temperature resistance, acid and alkali are limited.