Realize intelligent and flexible detection of networked devices

Release Date:2019-02-23 Author: Click:

On January 16, Zhang Shanshan and Ren Chuan, in charge of the test, were at Workstation A3 of the Material Quality Intelligent Inspection Center (hereinafter referred to as the "Testing Center") of the State Grid Liaoning Electric Power Co., Ltd., according to the electronic screen prompts, to connect the automatic take-up and pay-off devices one by one. Decentralized test test line. After clicking "Confirm" on the screen, the intelligent flexible detection system automatically starts 6 tests including voltage ratio measurement and connection group label verification test, winding DC resistance measurement test, no-load current and no-load loss measurement test for 10kV distribution transformers. . Compared with the traditional detection mode, the current detection time is shorter, the accuracy rate is higher, and the operation is smarter and faster.

With the development of power grid construction, the State Grid Corporation of China has higher and higher requirements for equipment sampling, and the scope of inspection continues to expand and the number continues to increase. In August 2017, the State Grid Liaoning Electric Power Material Quality Intelligent Inspection Center was put into operation. The testing center is composed of three parts: the main control room, 8 testing stations and the sample warehouse. It reliably detects samples through the intelligent flexible testing system to ensure that high-quality equipment is provided for the safe operation of the power grid. At present, the testing center is able to achieve more than 100 test projects for 16 types of power distribution equipment such as distribution transformers, switch cabinets, current transformers, and voltage transformers. After it is fully completed, it can cover the testing capabilities of 26 types of materials.

Automatic equipment realizes intelligent detection

The intelligent flexible detection system can automatically provide detection schemes according to the types of power materials and detection requirements, organically soften various electrical test items to the same assembly line, automatically complete the control, measurement, and test data analysis and management of various test items, and Generate the final inspection report.

The operating platform of the intelligent flexible inspection system is set in the main control room of the inspection center. Cao Jian, the person in charge of the field, used the "brain" to compare the system vividly: "It is both the starting point and the ending point, with functions such as monitoring, equipment management, standard management, storage of raw data, data judgment and analysis, and test report generation. And can understand the status and results of all test tasks in real time through the system."

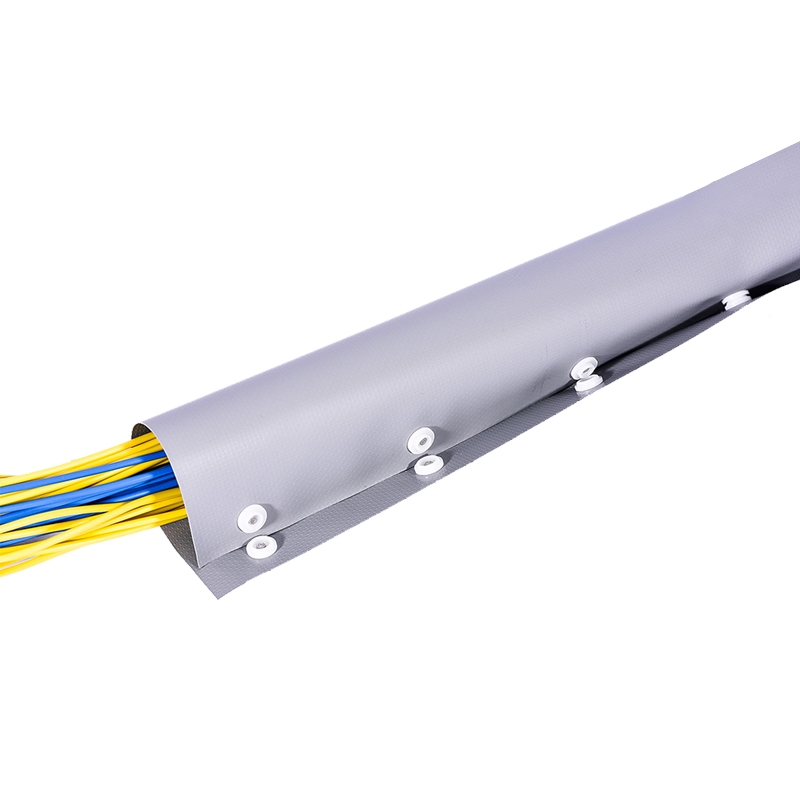

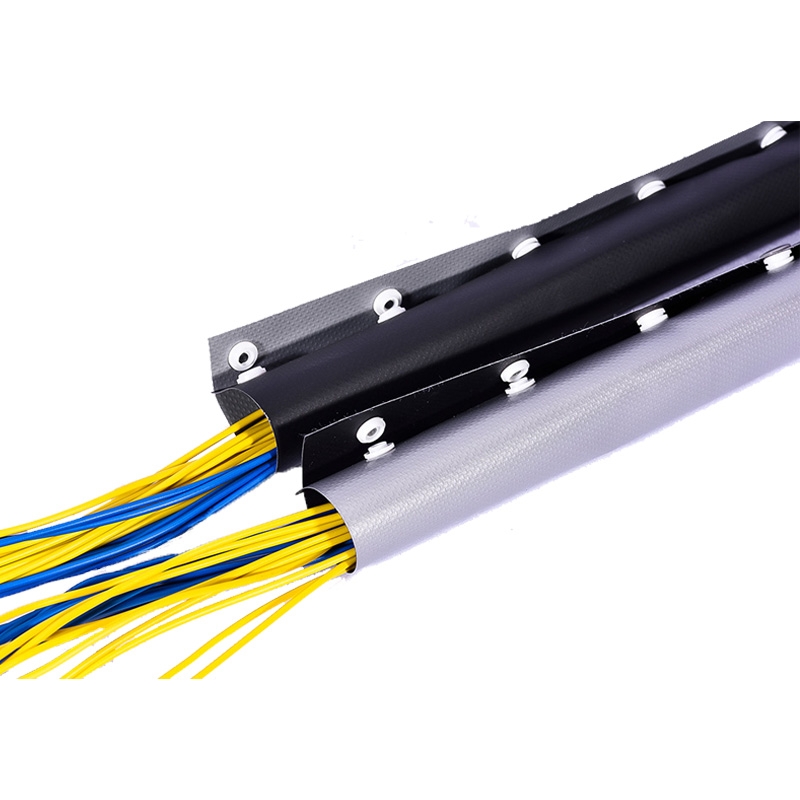

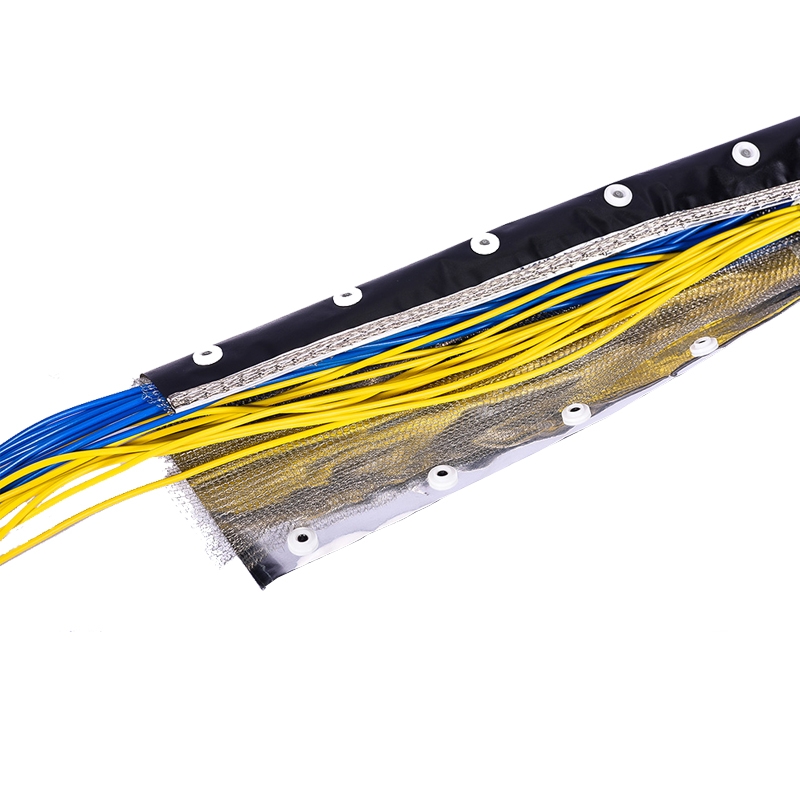

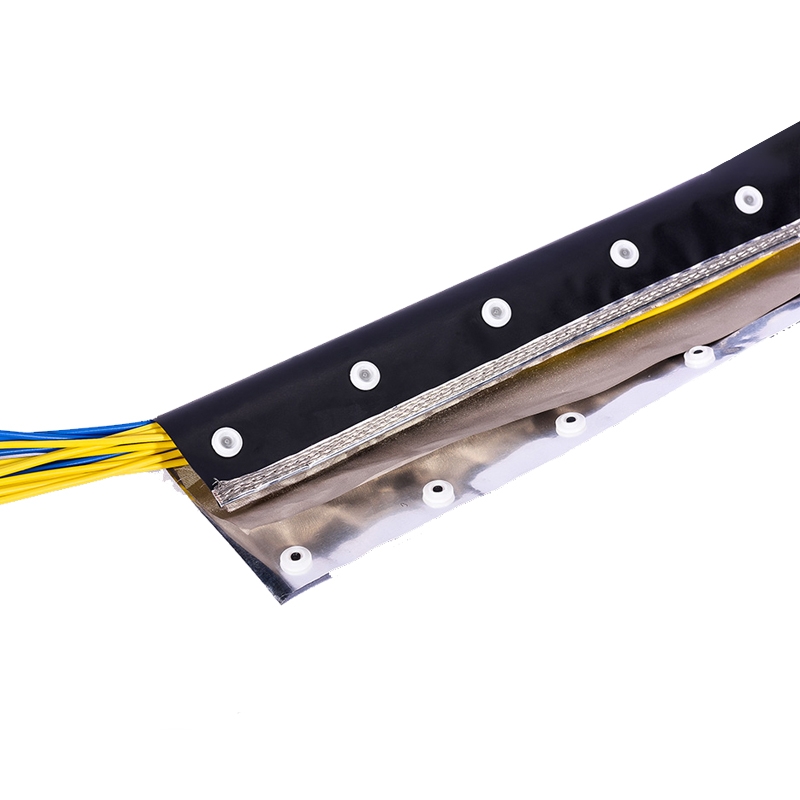

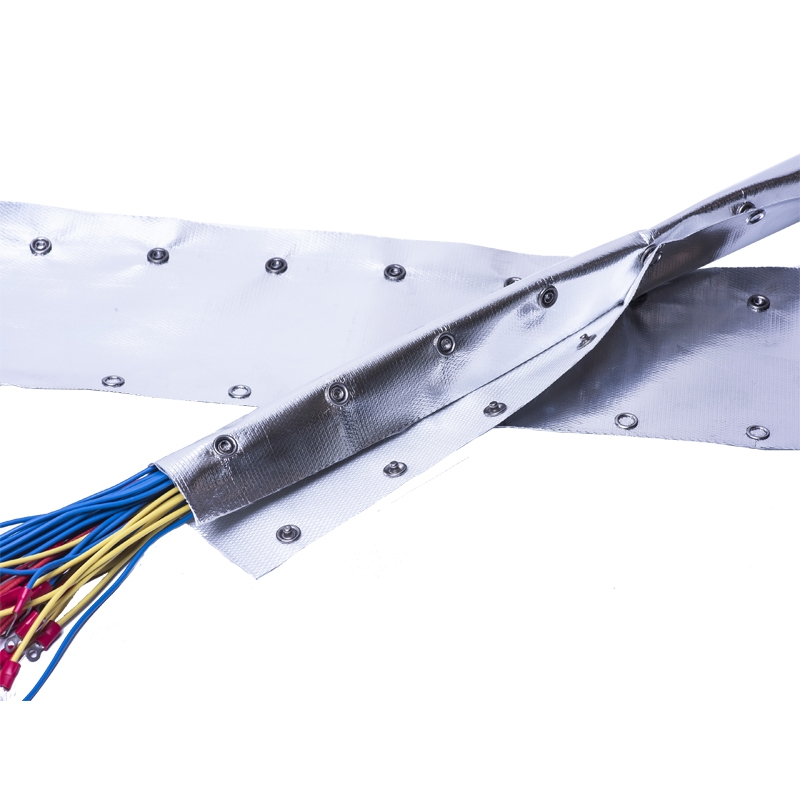

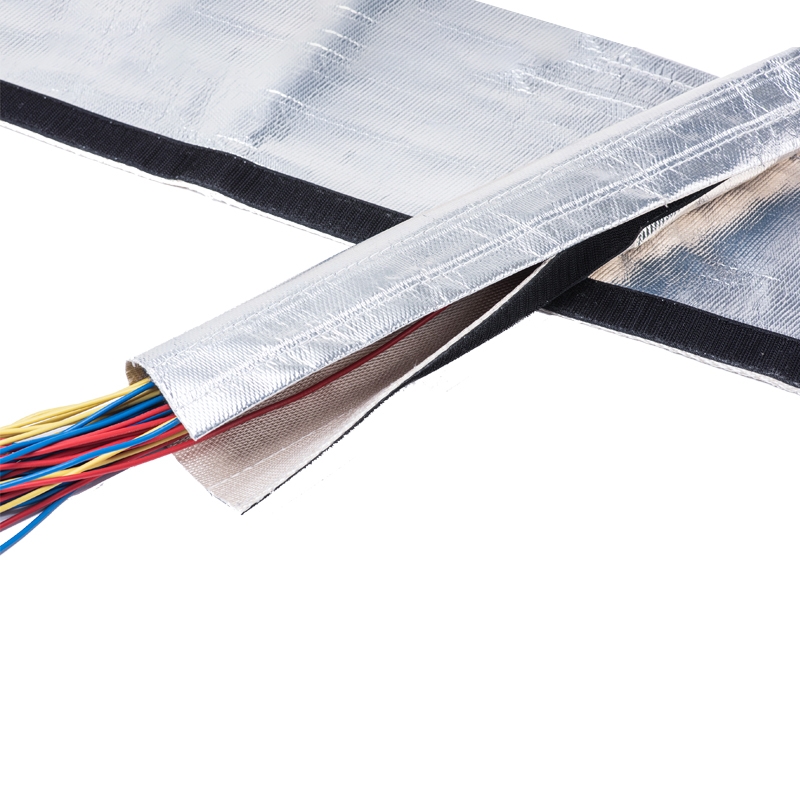

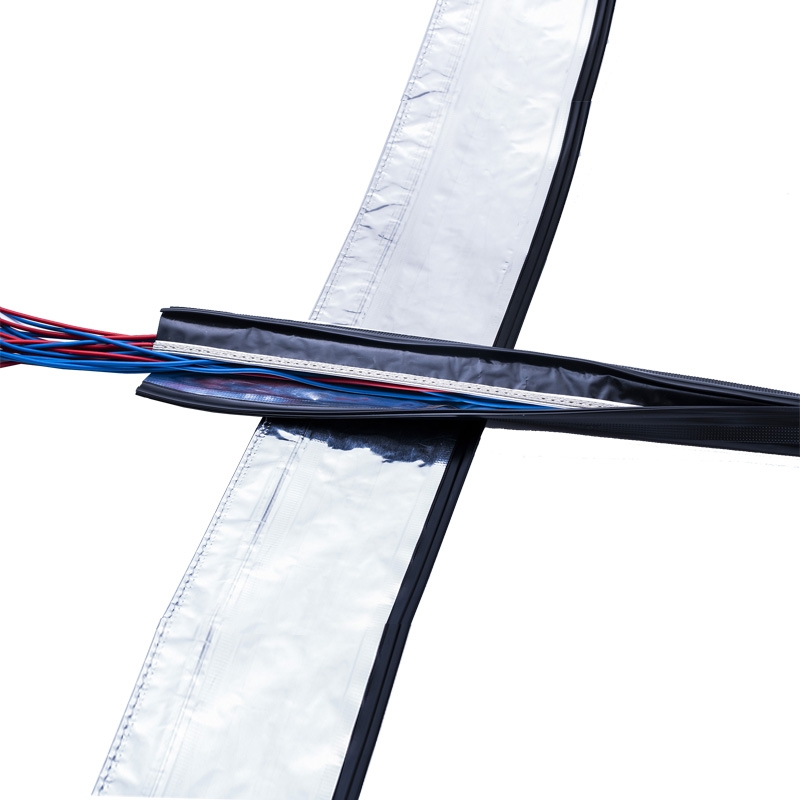

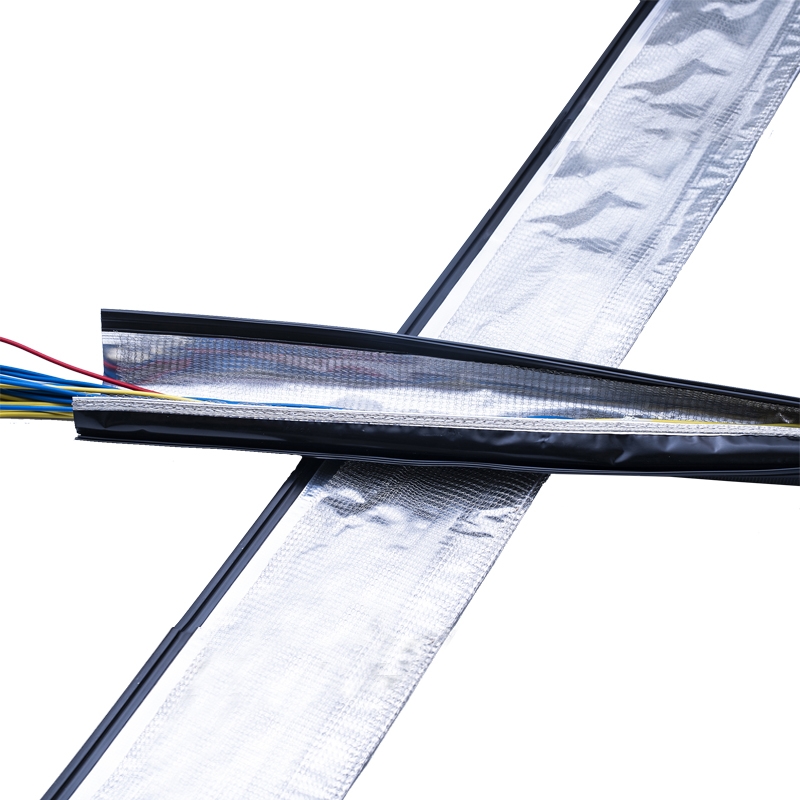

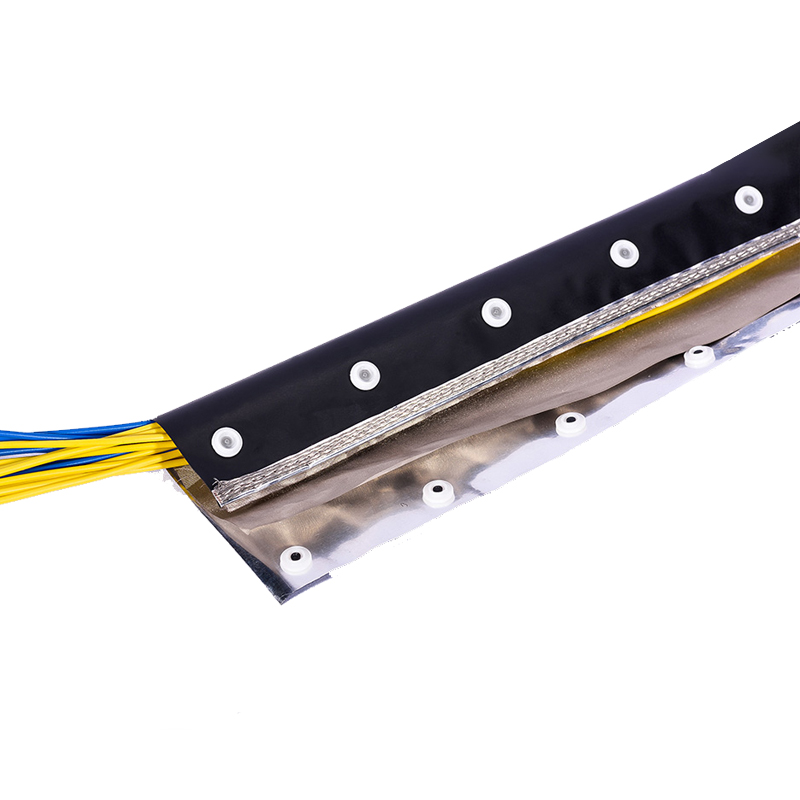

In the testing center, "button casing" and "intelligence" are vividly reflected. The overall inspection process is controlled by the central control system, which effectively improves the safety of the entire inspection process and the authenticity and accuracy of the test results. Among them, automatic retracting and unwinding technology, no manual operation after the test product enters the station, the system automatically releases the test line group required for the test product, and the system automatically retracts the line group after the completion of the test is removed; the automatic detection process, test The station automatically judges sample parameters and measures automatically according to the test tasks assigned by the system. Except for manual wiring and start-up measurement, other steps are automatically completed; intelligent storage of test data, regular backup to ensure safety, test data can be in line with industry standards and history Data horizontal and vertical comparison, icon analysis, and automatic generation of inspection reports.

"In 2018, State Grid Liaoning Electric Power will continue to further promote the intelligent inspection of material quality, supplement and improve existing inspection equipment, and will add other test items to further improve inspection and test capabilities." Deputy Chief Engineer of Liaoning Electric Power Research Institute Han Honggang said.

New technology application improves work quality and efficiency

At present, the intelligent flexible detection system, which is at the leading level in China, can reduce the labor intensity of the inspectors and enhance the safety of the inspection process by improving the efficiency of test detection button casing, the efficiency of sample transfer, the efficiency of data management and the level of safety assurance. Improve the quality and efficiency of material inspection, and realize the automation, intelligence, information and systematization of material inspection.

Compared with the time-consuming and labor-intensive traditional detection mode, the intelligent flexible detection system has many advantages.

Cao Jian still took the six inspections carried out at one time for the 10 kV distribution transformer at station A3 as an example. The intelligent flexible inspection only takes 60 minutes and can be completed by two people. Compared with the traditional inspection mode, it saves about 50% of labor costs and reduces The production cost is about 80%, and the detection efficiency is improved by more than 300%. Based on this calculation, according to the calculation of normal working days throughout the year and 3 inspection stations, the annual inspection volume of distribution transformers can reach 400 units, and the limit annual inspection volume can reach 900 units.

Compared with the traditional detection mode, intelligent flexible detection realizes the automatic transfer of test products, has the advantages of intelligent transmission, unmanned operation, safety and efficiency, etc.; realizes the intelligentization of the test, and has the advantages of one-time wiring, one-operation, and intelligent testing; It has realized the informatization of data management, and has the advantages of automatic collection, automatic analysis, and automatic archiving. It has realized the systematization of safety protection, and has advantages of system protection, safety protection, and lockout management and control.

In the specific inspection, the intelligent flexible inspection system has carried out the quality inspection and performance verification of power distribution equipment, and promoted the performance and quality random inspection of a variety of new equipment, which greatly improved the material inspection ability of the State Grid Liaoning Electric Power. As of the end of 2017, the testing center has been in operation for 3 months. Among the more than 100 test products tested, more than 30 transformers, 1 box-type substation, and 1 ring network cabinet have been found to be unqualified, ensuring the deduction of materials into the network. The quality of the type casing provides safe material guarantee for the construction of a strong smart grid.

Standardized management to improve detection level

In the whole process of intelligent testing, partial discharge test and withstand voltage test are an important assessment to verify the quality of the test product, and put forward high requirements on the testing environment. "All need to be carried out in a closed shielded room. The layout of high-voltage equipment strictly follows the electrical safety distance design required by national regulations, which will shield signal interference, and the partial discharge in the shielded room fully meets the national requirements to ensure the safety of the test environment."

Chen Yiming, who is responsible for the test, is about to start the partial discharge and withstand voltage test of the 10kV switchgear. Before the test, Chen Yiming realized remote control via a tablet computer. "I want to scan the exclusive QR code of the switchgear with a tablet to establish a one-to-one relationship, and then upload the relevant parameters to the newly created logic module to generate a test task list, and the system automatically determines the test items, sequence, wiring and process." After 5 minutes of preparation, Chen Yiming clicked "Confirm" and completed the 3 tests in just 200 seconds. If it was before, it may take nearly a day.

In order to achieve a standardized management level for the testing center, State Grid Liaoning Electric Power has continuously improved various regulations and systems, established the development concept of "Talent Work Priority", and continuously improved and enriched the evaluation criteria for talents. The company focused on standardizing requirements for intelligent testing, clarifying that the movement of test products is automatically completed by the intelligent mobile platform; separating people and equipment by dividing test areas, equipment transportation channels, and dedicated personnel channels to ensure the safety of personnel during the test. The test process is implemented by the measurement and control software according to the prescribed process. Each station is equipped with warning lights and alarm bells. The warning lights display different working states of the detection stations through flashing and color change. There will be voice prompts throughout the test, and the nodes that require personnel intervention will have corresponding voice prompts, which is convenient for personnel to deal with in time.