Application of heat shrinkable tubing in cable welding

Release Date:2021-07-19 Author: Click:

As an intermediate link that connects the various functional components of the entire electronic system, cables are widely used in the aerospace field and marine carrier platforms. They are distributed in a variety of working environments, and their performance is particularly stable. important. Because any solder joint with poor contact or poor welding quality will have an unpredictable impact on the entire system. Cables are like the blood vessels and nerves of the human body. Problems with the main blood vessels and nerves of the human body will cause death, and the unreliability and unsafeness of the cables will affect the realization of the function of the entire system.

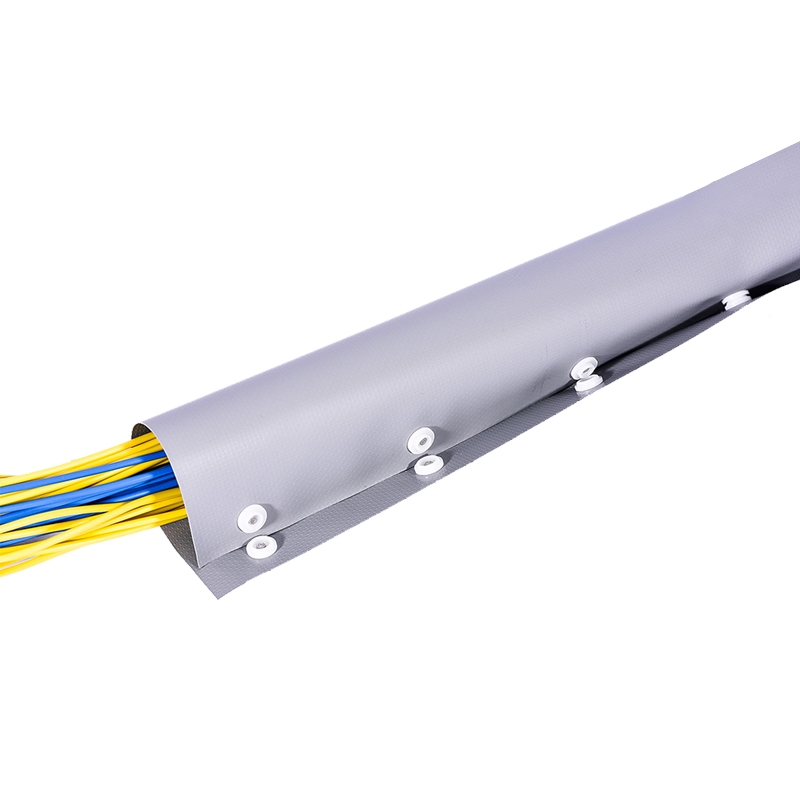

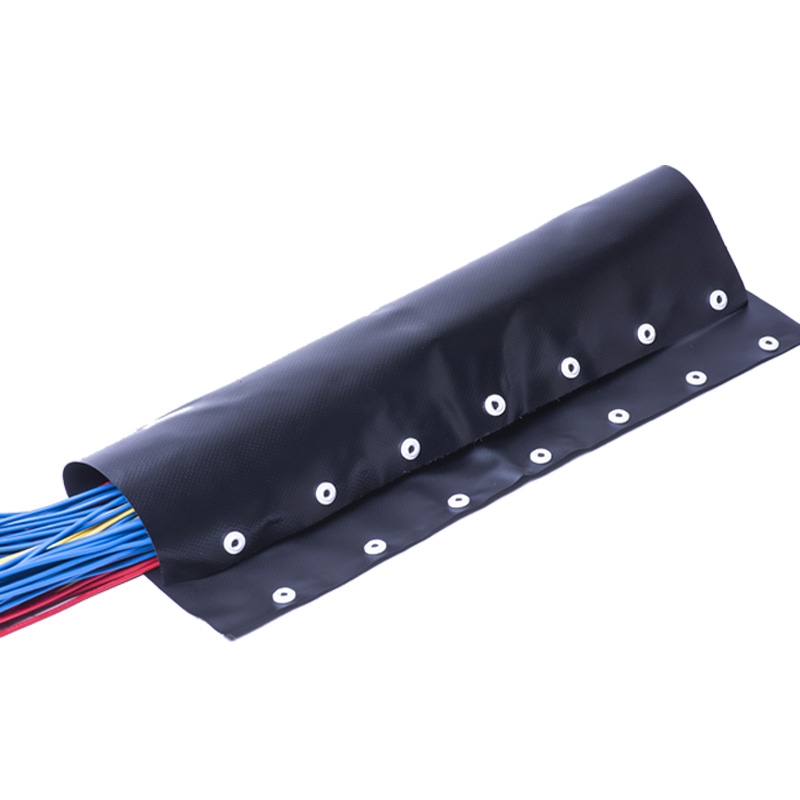

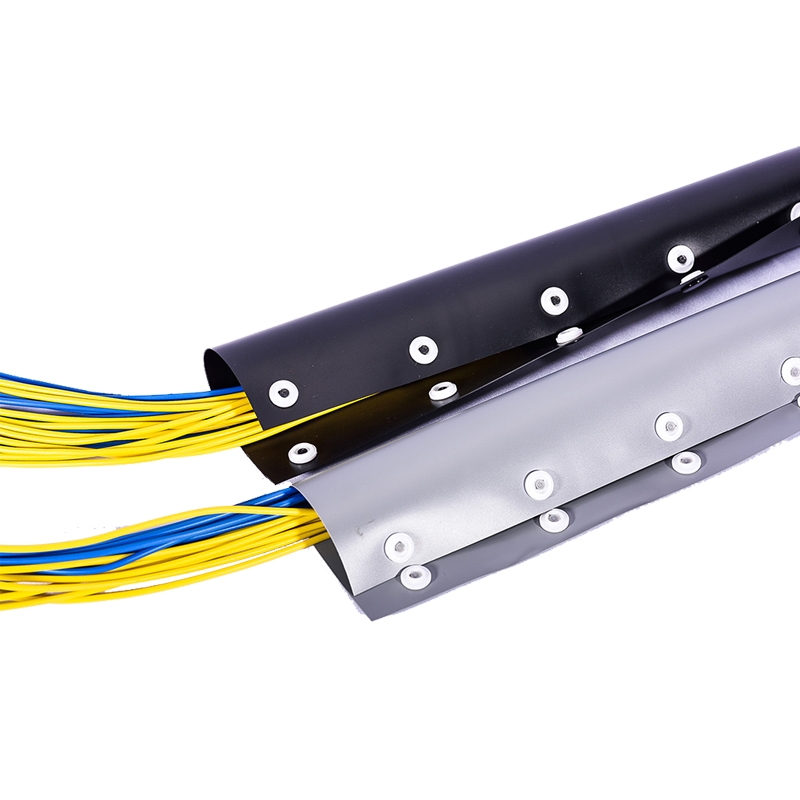

In order to prevent moisture and dust, a layer of heat shrinkable tubing is required to protect the electrical connector and the cable connection. The selection of Teflon tubing should be based on the size of the electrical connector tail attachment and the outer diameter of the cable. The length should be from After the outer screw sleeve of the electrical connector can shrink a part of the cable, the length of the retracted cable is generally about 2 times the outer diameter of the cable. For example, for a cable with a diameter of 150px, the heat shrinkable tube should be able to shrink a cable with a diameter of about 250px.

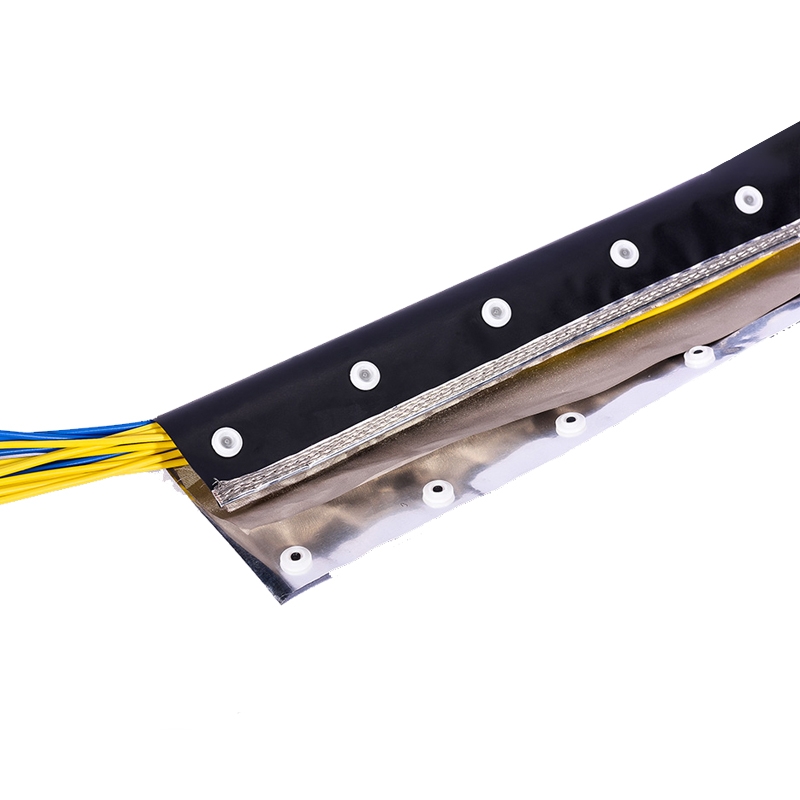

After all the core wires are welded, the spare wires are covered with heat-shrinkable sleeves. Tighten the tail cover, tighten the top wire, wrap several layers of insulation tape between the cable surface and the compression ring, lead the core wire shielding layer or inner shielding layer, and make a cold-rolled end at the end. Tighten one screw of the tightening ring, and then tighten the screws at both ends of the tightening ring to flatten the spring pads. After the tail cover is installed, it should be connected to the cable tightly without shaking. Shrink the heat shrinkable sleeve to the highest position that does not hinder the rotation of the outer screw sleeve, and the other section should wrap the cable at least not less than 2 times the diameter of the cable. If the diameter of the cable is too small, and the structure of the tail of the electrical connector is large, and the cable cannot be shrunk after the tail is tightened, then a relatively thin shielding sleeve must be added to the tail of the previous heat shrinkable sleeve. , And combine it tightly with the cable. Finally, shrink the cable identification at a distance of 125px from the end of the heat shrinkable sleeve or the tail of the electrical connector. When shrinking, make sure that the side of the cable identification is consistent with the position of the electrical connector No. 1, that is, on a horizontal surface. Moreover, it is best to use a heat gun to blow from the back of the label when shrinking, so that the font of the label will not shrink too much and cause unclear and difficult to recognize.

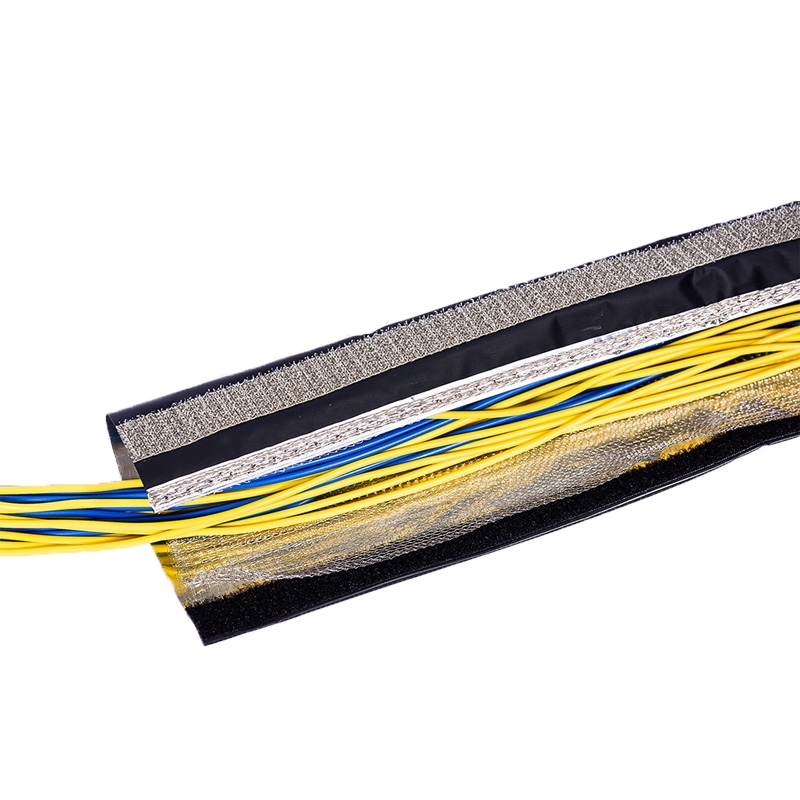

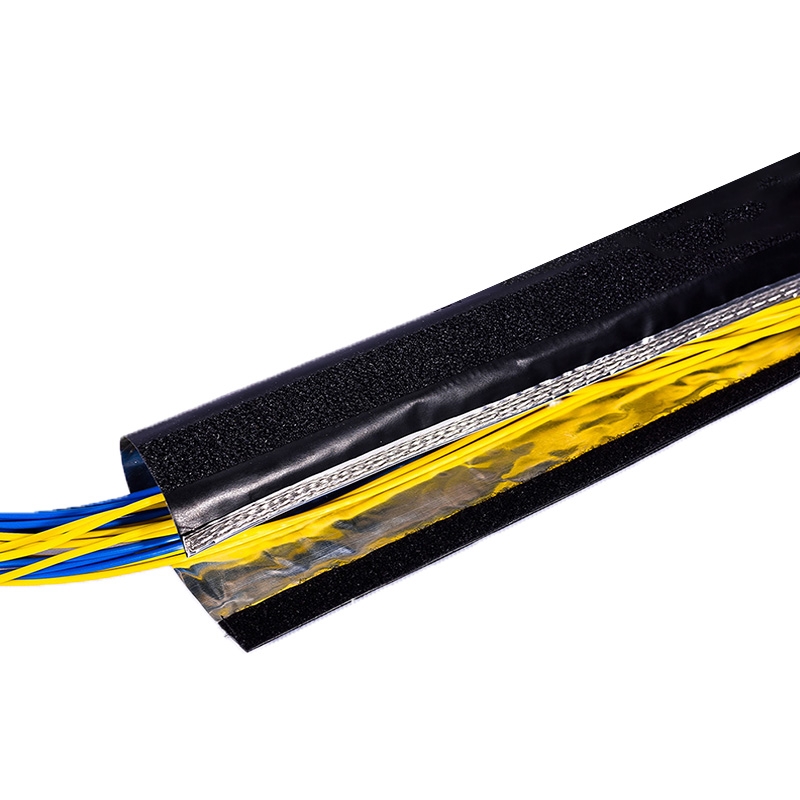

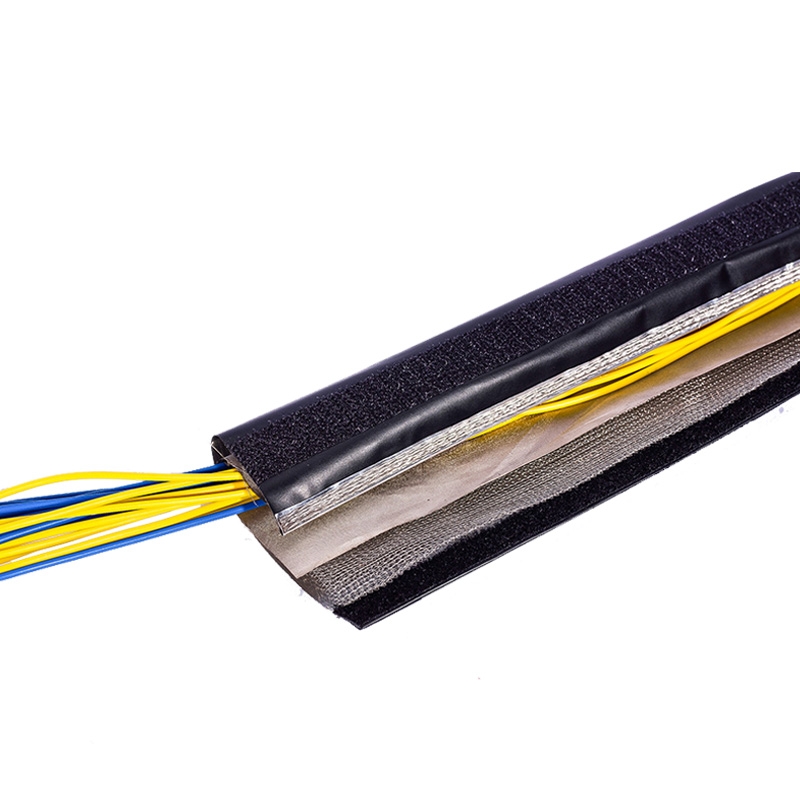

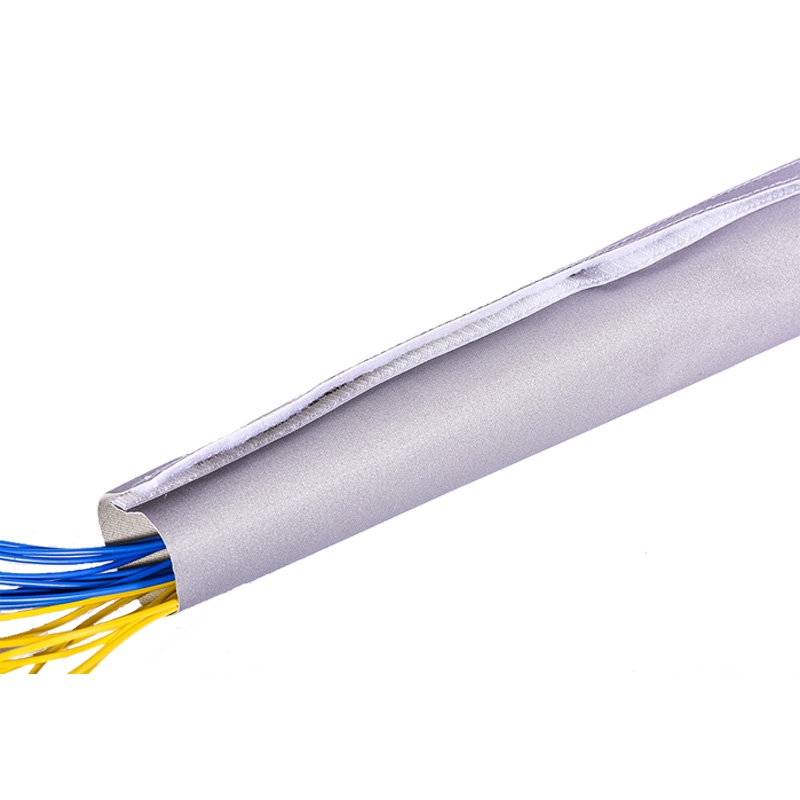

The heat shrinkable tubing involved in this article is divided into two categories.

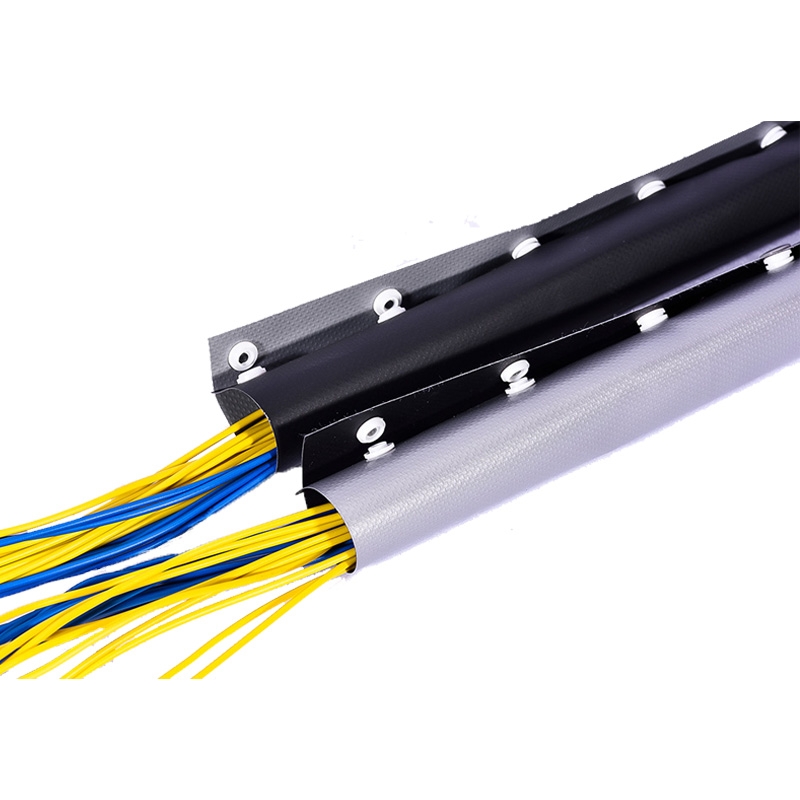

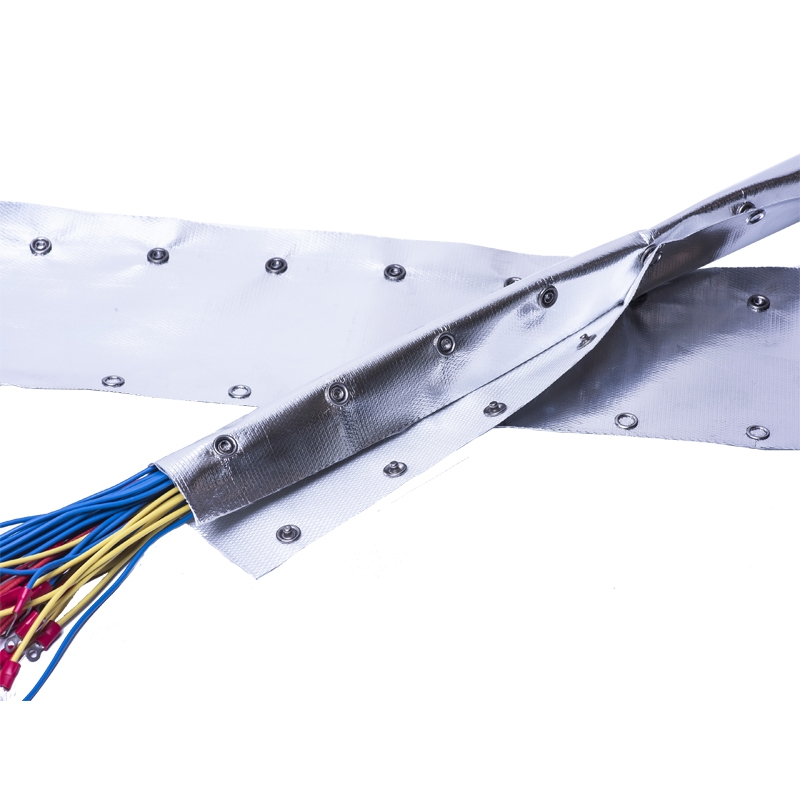

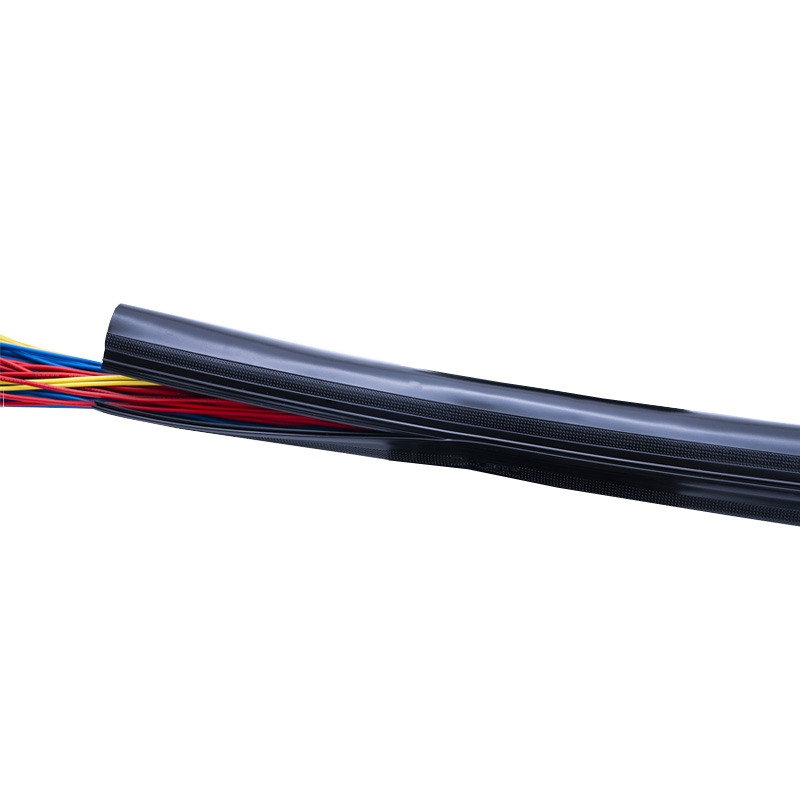

One type is used to protect the connection between the electrical connector and the cable with a hot melt on the inner wall. The glue on the inner wall of this glued heat shrinkable tube will melt after heating. After cooling, it will have a good moisture-proof effect. hardness.

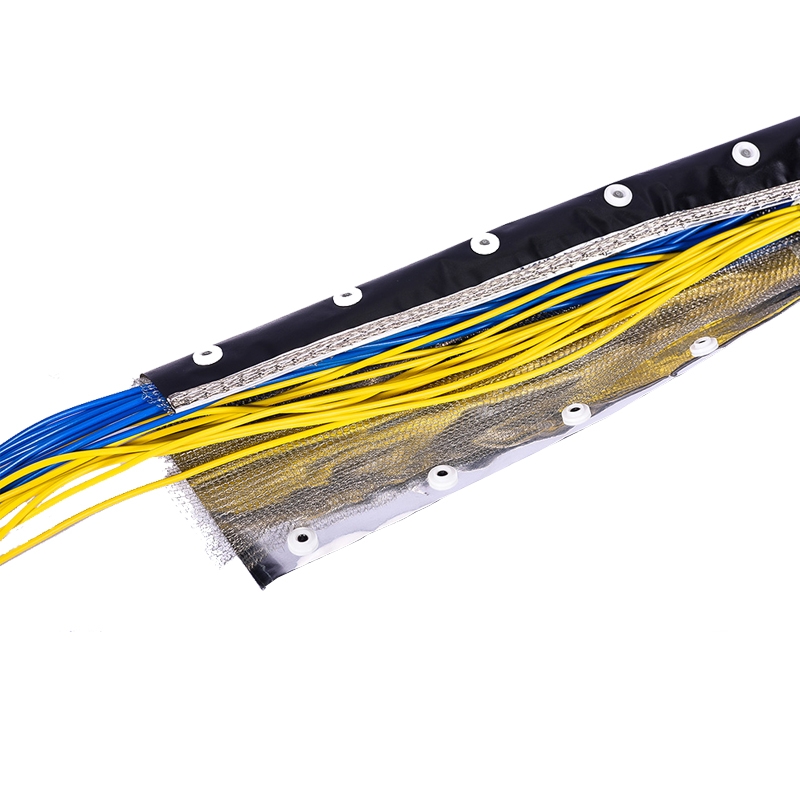

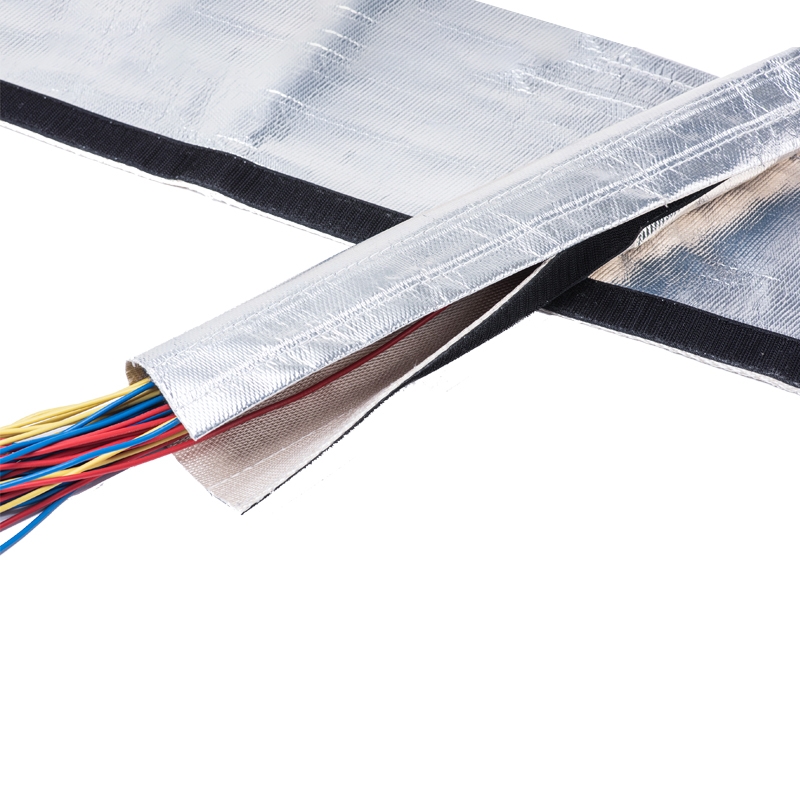

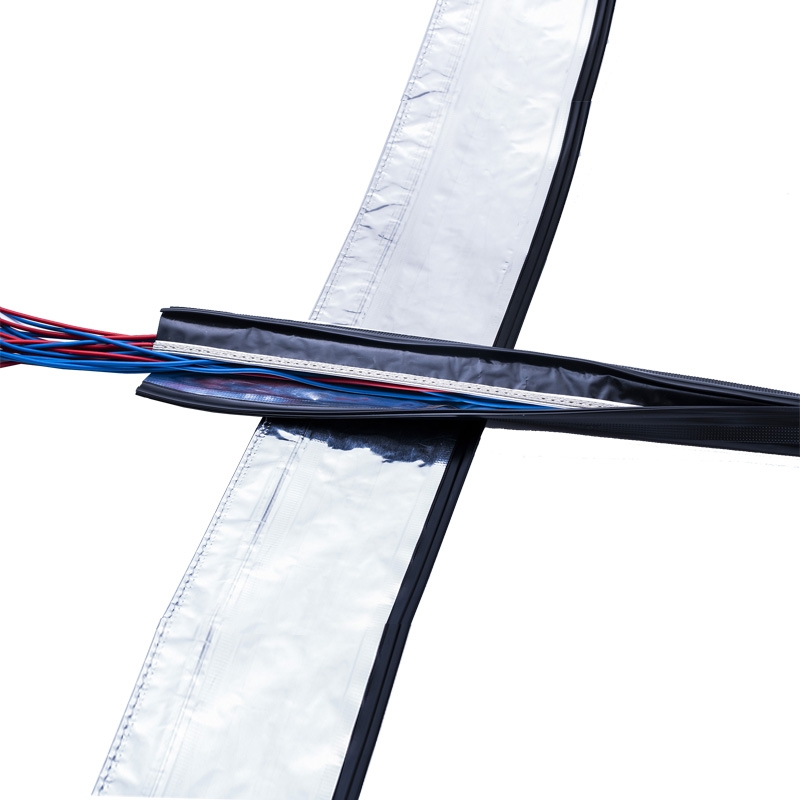

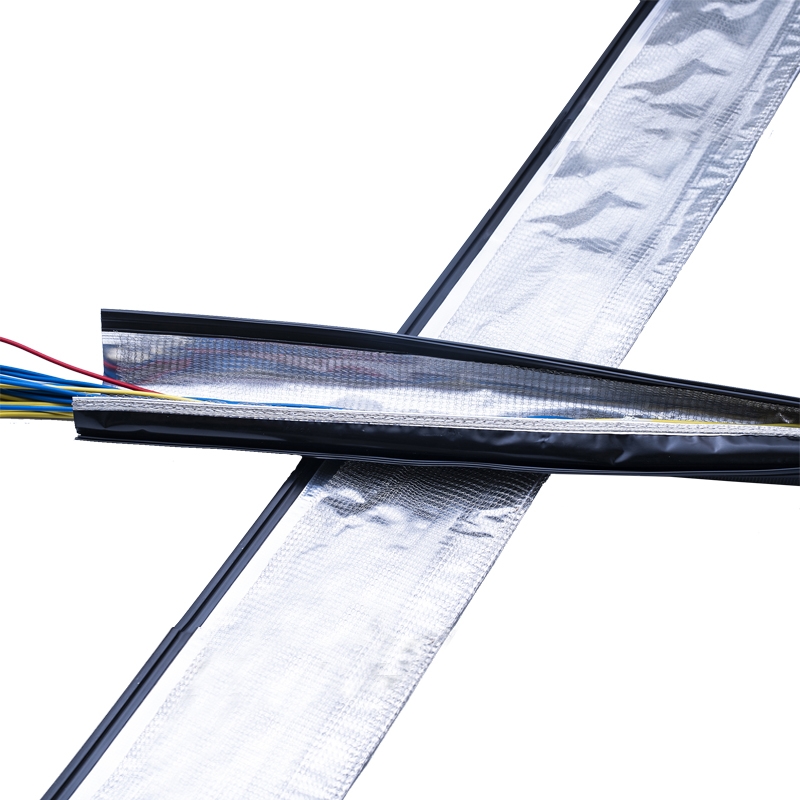

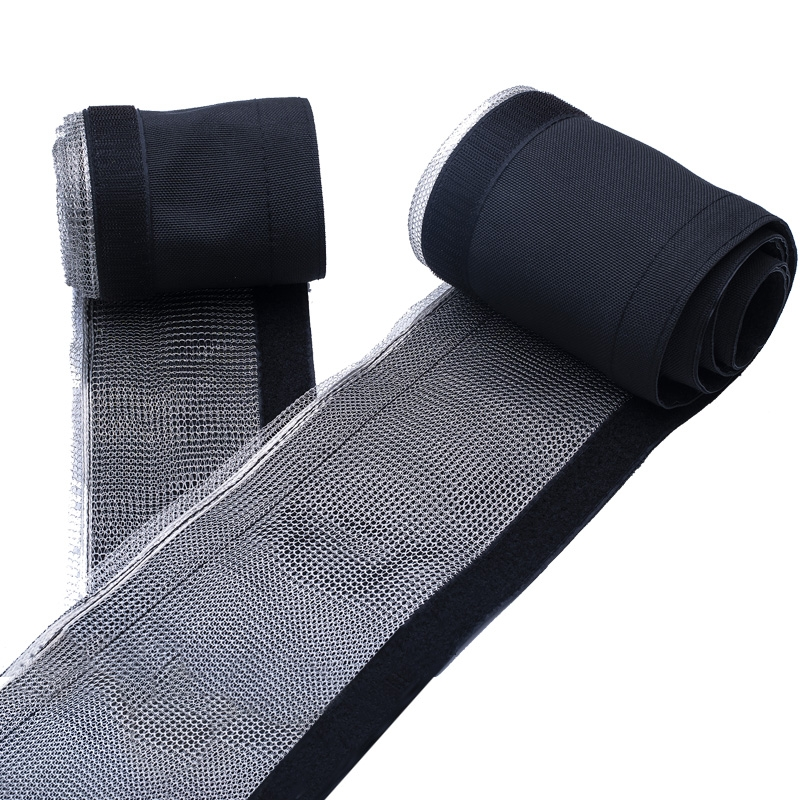

One type is a high temperature resistant sleeve with no glue on the inner wall, which is relatively soft after heat shrinkage. One of them is a braid-type package that can be printed with marks and used as an identification sleeve. One is a transparent heat-shrinkable tube used to protect the cable identification, which is often used to identify the protective tube. There is another type that can be used for end protection of spare wires and end protection of core wire shielding layer.

The use of heat shrinkable tubing must fully consider the size before and after heat shrinking, that is to say, when selecting, it must be slightly larger than the size of the package before heat shrinking, and the size after heat shrinking must be less than the total outer diameter of the package, so as to ensure heat shrinking The effect of the casing.