Improve the service life of high temperature resistant casing

Release Date:2021-07-05 Author: Click:

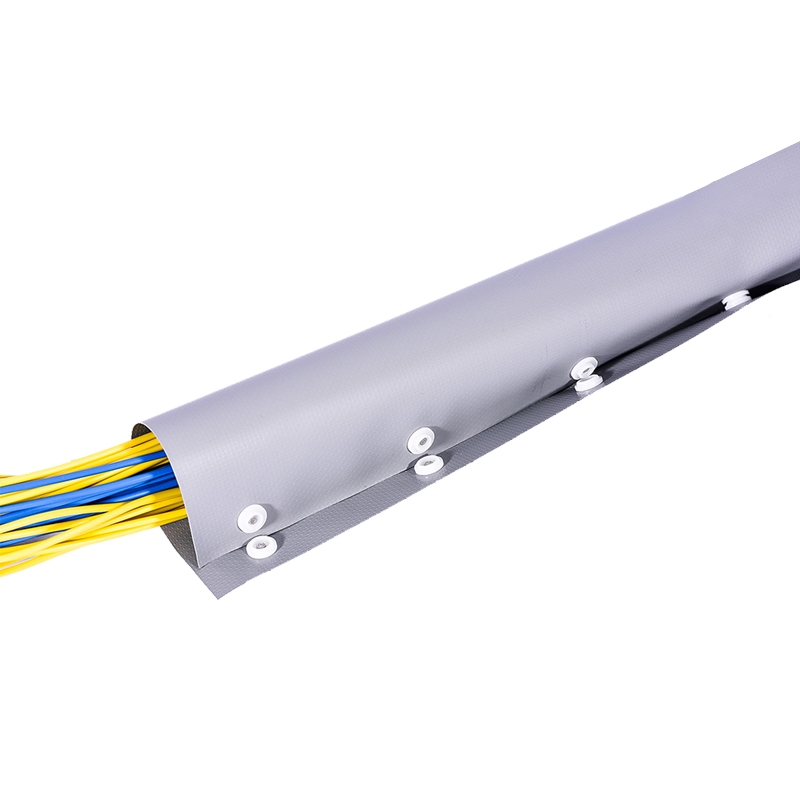

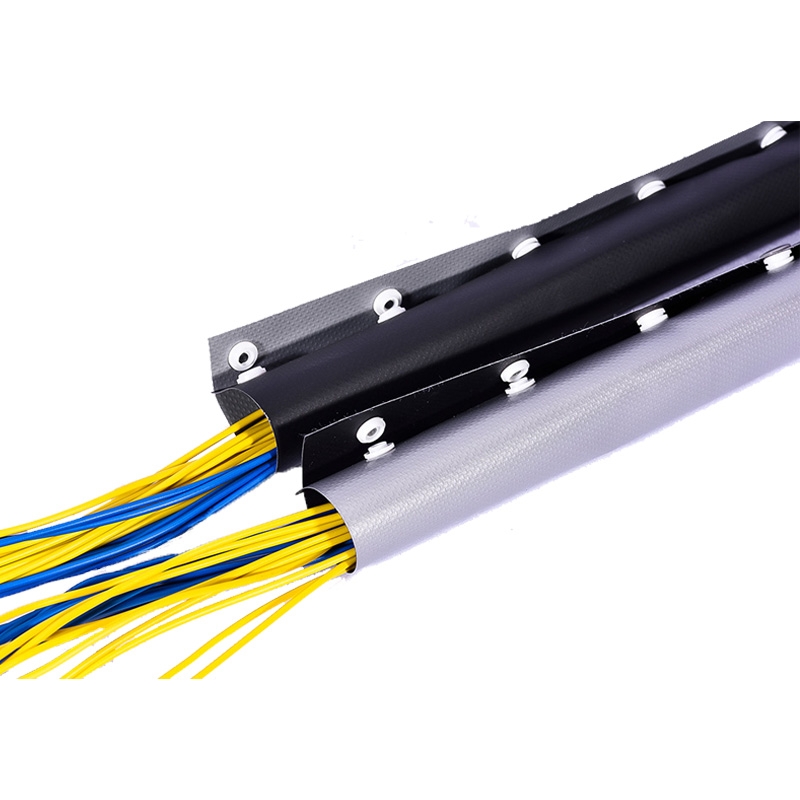

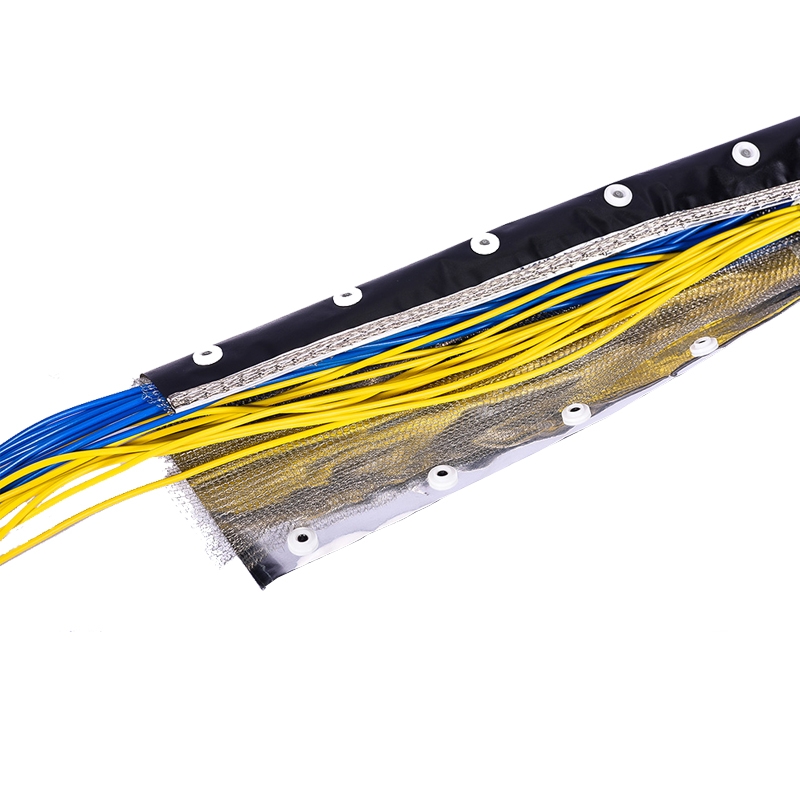

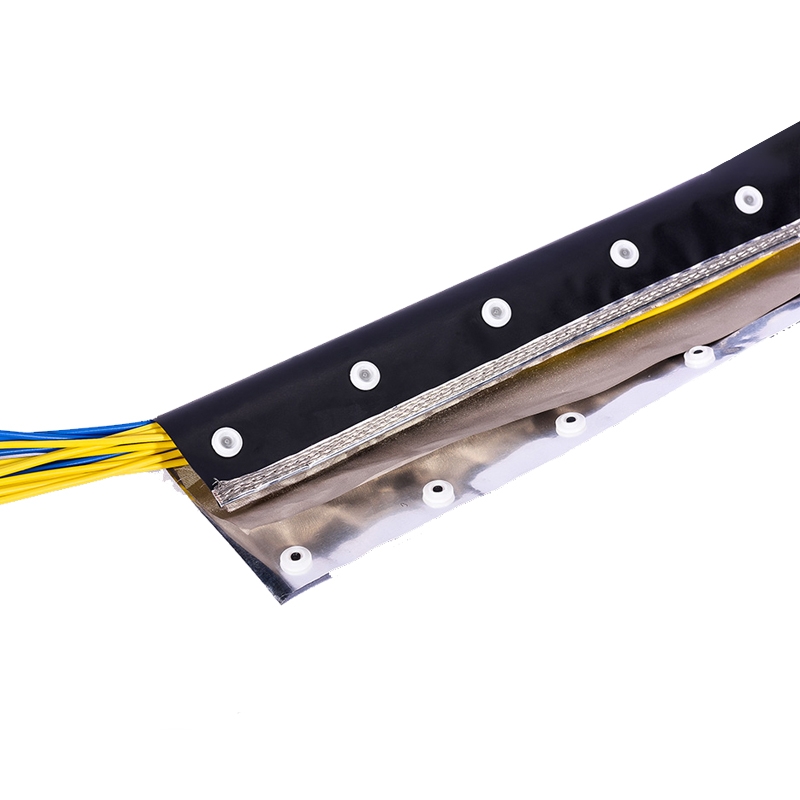

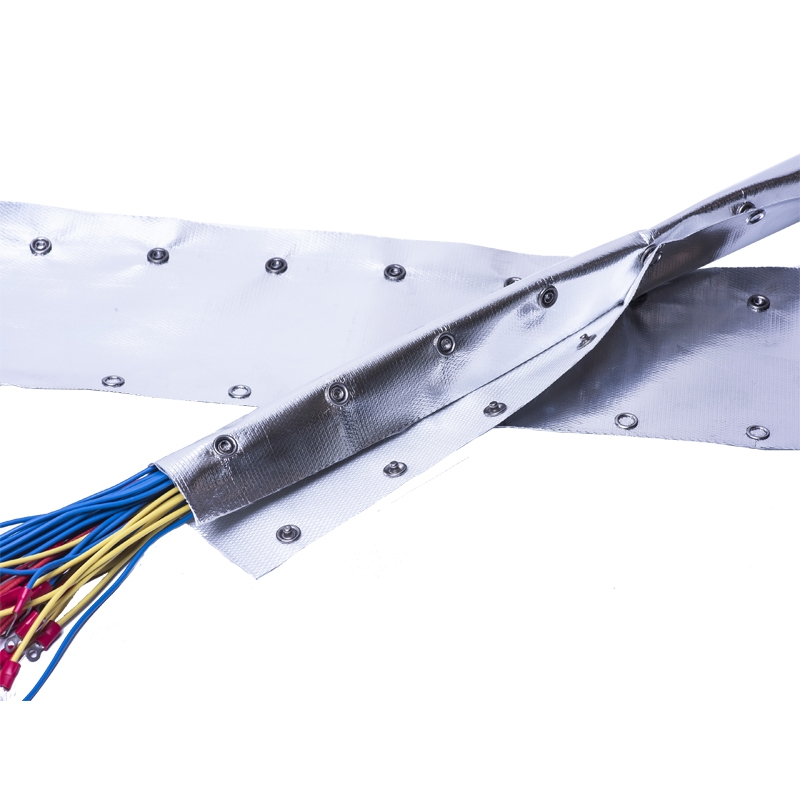

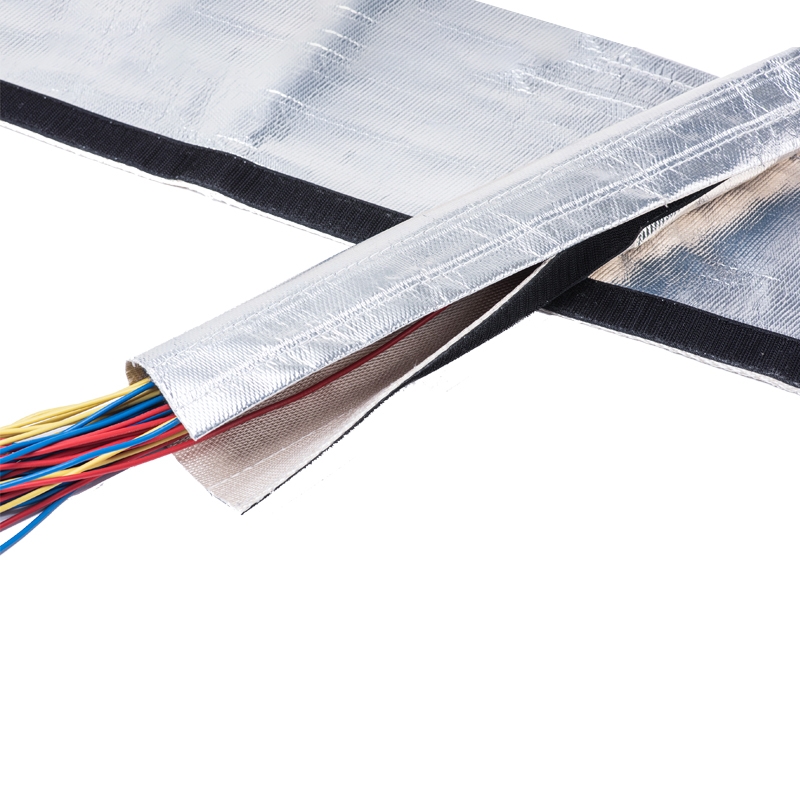

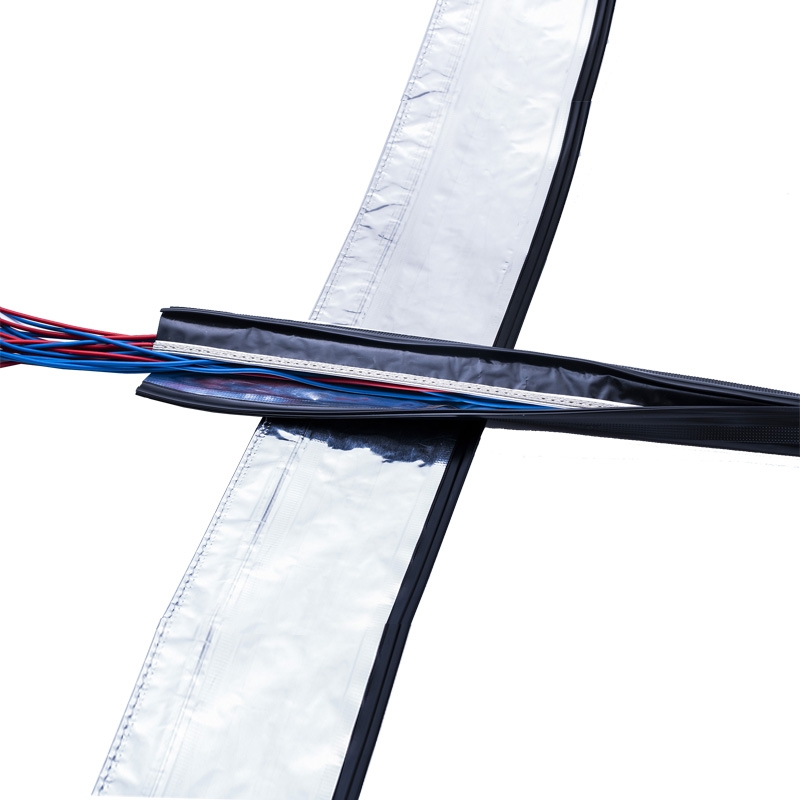

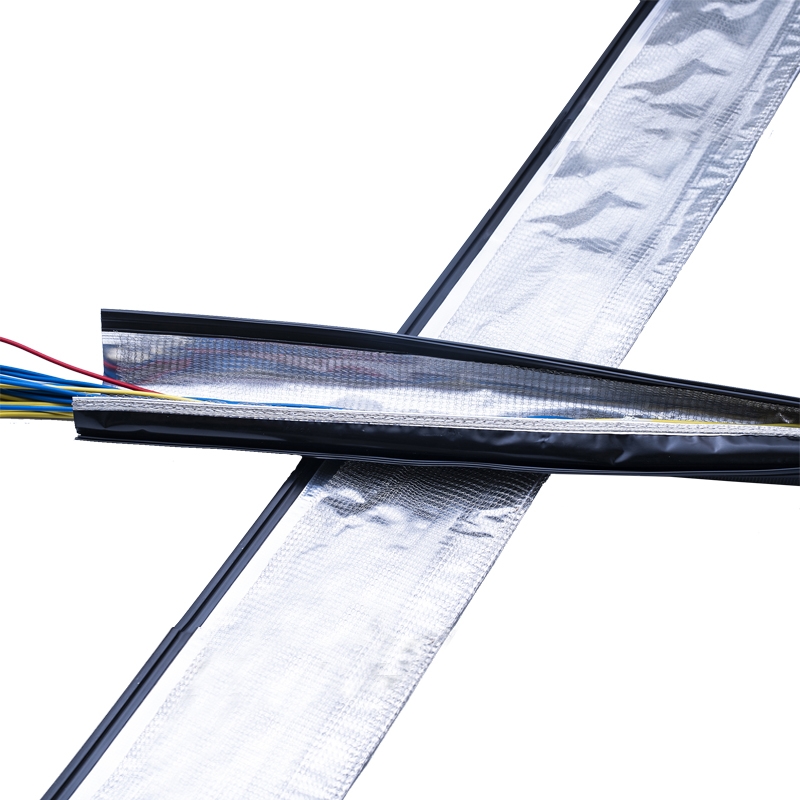

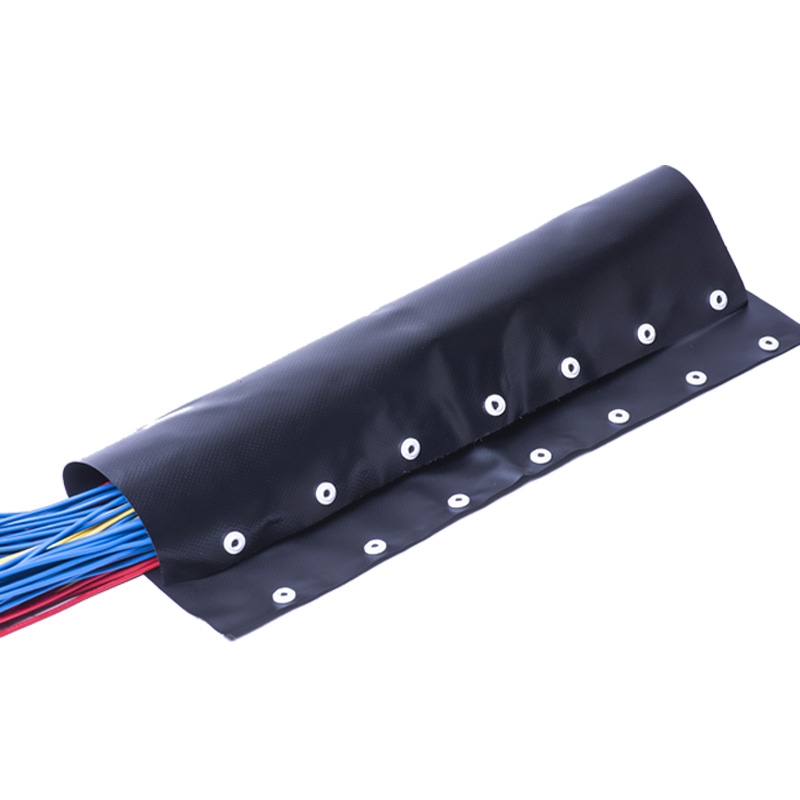

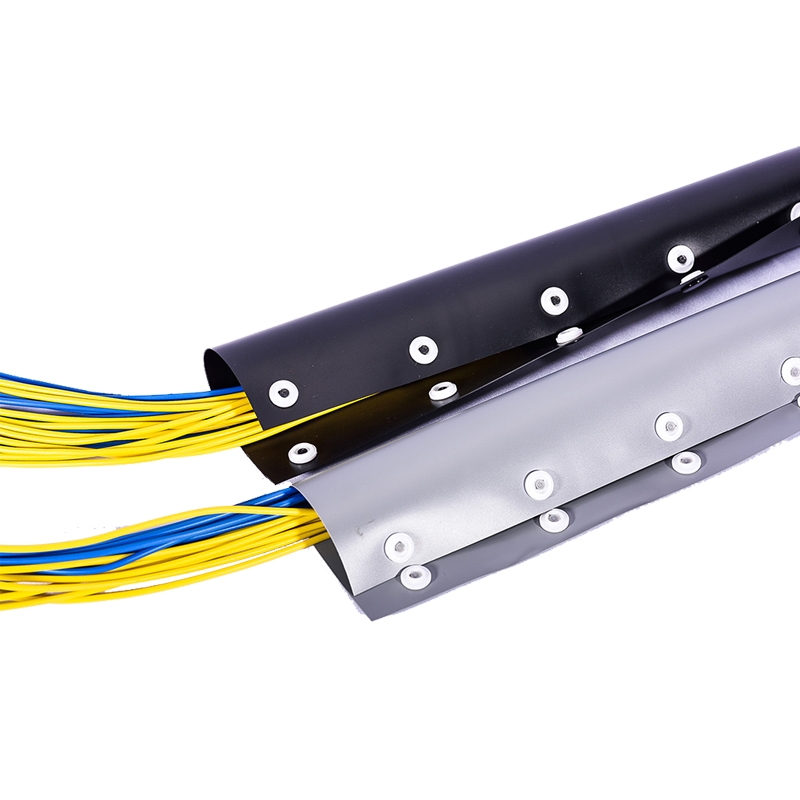

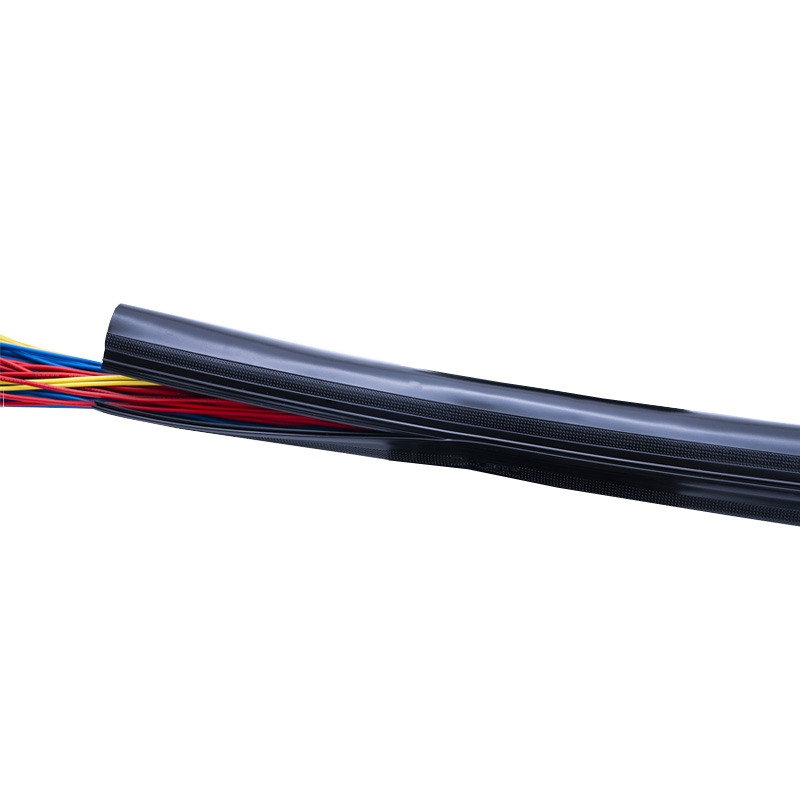

The fire-resistant and high-temperature resistant casing is mainly used to protect various pipeline equipment from damage. It can effectively protect the pipeline equipment from baking in a high-temperature environment. It can also prevent various corrosive substances that occur during operation from damaging the pipeline equipment, thereby reducing its performance. The aging speed, continuous its service life.

In the face of full-featured fire-resistant and high-temperature resistant casing, several points must be considered when using it to prevent improper use from reducing its service life and aggravating the protection costs of enterprise pipeline equipment. Because the surface is coated with silicone, its main chain is -Si-O-, and there is no double bond, so it is not easy to be differentiated by ultraviolet rays and ozone. Fire-resistant enclosures have good electrical insulation functions. Their dielectric loss, voltage resistance, arc resistance, corona resistance, volume resistivity and surface resistivity are the best in insulation materials, and their electrical functions are affected by temperature and The influence of frequency. The impact is small. Manufacturers of high-temperature fire-resistant casing introduced that they are stable electrical insulation materials and are widely used in the electronics and electrical industries. If the pipeline transports flammable or toxic media, leakage may cause fire or casualties

Of course, the unqualified quality of the fireproof casing will also cause the phenomenon of insufficient protection. If the quality is problematic, it will not play the expected protective effect when used, and it will also affect its overall protective effect.